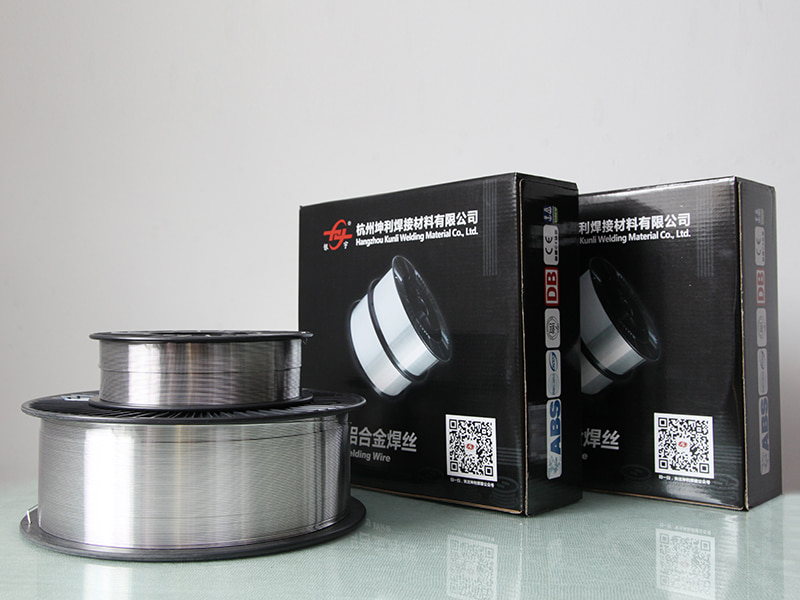

Aluminum Welding Wire

Special Al Alloy Welding Wire

This special Al alloy filler metal, containing Sc and Magnesium, provides high strength, great seawater corrosion resistance, and a uniformly distributed fine cubic crystal structure. It is recommended for welding parts in the 5000, 6000, and 7000 series, with commonly used grades such as Aluminum Welding Wire ER4943, especially suitable for Al-Mg-Sc and Al-Zn-Mg-Sc alloys. The material is widely applied in aerospace, military, rail transit, and automobile industries.

Special Al Alloy Welding Wire Product Features

Excellent high temperature performance: The welding wire has excellent high temperature strength and creep resistance by adding some refractory metal elements, and can maintain a stable welding effect under high temperature environment.

Good welding performance: The melting process is stable and there is no spatter. The welding wire has good flow and spreading between layers, and it is not easy to have defects such as side wall unfusion, which can form a beautiful and defect-free weld.

Excellent crack resistance and mechanical properties: Taking 2195 aluminum-lithium alloy welding wire as an example, its fusion welding joint is mainly composed of α-Al, Al₂Cu, Al₃(Ti,Zr) phases, with excellent crack resistance and mechanical properties, extremely low crack sensitivity, and the tensile strength of the joint at room temperature is about 390MPa, and the elongation is 6.3%.

Product Parameters

Material: Mainly composed of aluminum and a variety of alloy elements, the specific composition will be adjusted according to different application requirements.

Diameter: Common diameter specifications are 1.2mm, 1.6mm, etc., and other diameters can also be customized according to customer requirements.

Length: Usually supplied in the form of spools, and the length of each spool can be customized according to customer needs.

Working current: Generally, DCEP (direct current reverse connection) current is required.

Working temperature: Operate at standard temperature.

Application Scenarios

Aerospace field: Used for manufacturing and repairing aircraft structural parts, engine parts, etc., such as 2195 aluminum-lithium alloy welding wire can be used for welding related parts in aerospace engineering.

Automobile manufacturing industry: Suitable for welding of automobile bodies, engine parts, etc., and can meet the requirements of automobile manufacturing for welding quality and efficiency.

Machinery manufacturing field: Can be used for welding of various mechanical parts, such as aluminum alloy frames, robotic arms, etc.

Electronic and electrical industry: It is also widely used in the welding of electronic equipment housings, radiators, etc.

Special Al Alloy Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Why Choose Kunli TIG Welding for Precision and Control

Mar 02, 2026

Walk into most working fabrication shops today and you will notice something: welders who built their careers on wire-fe...

-

Why Do Aluminum Welds Keep Cracking — And What You're O...

Feb 27, 2026

Every joining operation in Aluminum fabrication requires thoughtful decision-making that influences the final component ...

-

Key Factors to Choose the Right Aluminum Filler Metal

Feb 23, 2026

When fabricators face a choice between filler materials for joining nonferrous metals, they often underestimate how prof...

-

Common Mistakes to Avoid When Using Aluminum Welding Wi...

Feb 20, 2026

Every fabrication shop has experienced the frustration of Aluminum welds failing inspection after hours of careful work....

Industry Information Extension

More Information About Special Al Alloy Welding Wire Suppliers

Anti Oxidation and Process Optimization for Porosity Free Aluminum Welding

In advanced manufacturing, Special Al Alloy Welding Wire is increasingly used in industries such as aerospace, new energy vehicles, and shipbuilding. However, aluminum alloy welding is prone to issues like porosity, cracks, and oxidation, significantly affecting weld strength and airtightness. Recent breakthroughs in Porosity-Free Welding Technology, particularly through Anti-Oxidation Treatment and Welding Process Optimization, have dramatically improved weld quality.

1. Core Challenges of Special Al Alloy Welding Wire: Porosity and Oxidation

During aluminum alloy welding, the molten pool easily reacts with hydrogen (H₂) and oxygen (O₂) in the air, leading to porosity. For example, 4043 Al-Si Welding Wire and 5356 Al-Mg Welding Wire can exhibit porosity rates as high as 5%-10% if shielding gas (e.g., Ar or He) purity is insufficient, far exceeding the industry standard of ≤1%.

Key Parameter Comparison:

| Wire Type | Typical Porosity Rate (Conventional Process) |

Optimized Porosity Rate (Anti-Oxidation Treatment) |

|---|---|---|

| 4043 Al-Si | 4%-8% | ≤1% |

| 5356 Al-Mg | 3%-7% | ≤0.5% |

| 2319 Al-Cu (Aerospace Grade) |

5%-10% | ≤0.3% |

2. Breakthroughs in Anti-Oxidation Treatment

The latest Anti-Oxidation Coating for Al Alloy Wire utilizes Nano-Al₂O₃ Passivation, effectively reducing hydrogen absorption during welding. Additionally, Low Dew Point Shielding Gas (dew point ≤ -50°C) further minimizes porosity risks.

Optimization Examples:

Wire Pre-Cleaning: Uses Acetone Ultrasonic Cleaning to remove surface oils.

Inert Gas Optimization: Employs Ar+He Mixed Gas (75% Ar + 25% He) to enhance molten pool stability.

3. Welding Process Optimization: Pulsed MIG and Cold Metal Transfer (CMT)

Traditional MIG welding often leads to excessive heat input, whereas Pulsed MIG Welding and Cold Metal Transfer (CMT) Welding precisely control the heat-affected zone (HAZ), reducing porosity.

For example:

CMT Welding can reduce porosity in 5xxx Al-Mg Wire by 70%.

Alternating Current TIG (AC-TIG) is ideal for 2xxx High-Strength Al Alloy, minimizing oxide slag.

4. Industry Application Cases

New Energy Vehicle Battery Tray Welding: Uses ER4043 Al-Si Wire + CMT Process, achieving porosity <0.5% and meeting IP67 sealing standards.

Aerospace Structural Welding: 2319 Al-Cu Wire combined with Variable Polarity Plasma Arc (VPPA) Welding delivers ultra-high-strength welds.

Understanding Aluminum Welding Wire ER4943 in Modern Applications

ER4943 Aluminum Welding Wire is widely recognized as an advanced filler material developed to improve upon traditional ER4045 and ER4043 alloys. Compared with earlier grades, ER4943 offers higher tensile strength while maintaining good ductility, making it a strong choice for critical welding applications.

One of the main advantages of ER4943 is its reduced tendency to crack during solidification, which improves welding reliability and lowers the risk of porosity. Thanks to its optimized silicon and magnesium composition, this wire ensures better strength performance, especially when used in the welding of 6000 series aluminum alloys.

In practical applications, ER4943 is often selected for structures that require a balance of strength and corrosion resistance, such as automotive components, rail transit systems, aerospace parts, and marine equipment. Its ability to provide clean weld appearance and stable mechanical properties makes it an important option for industries demanding both performance and durability.