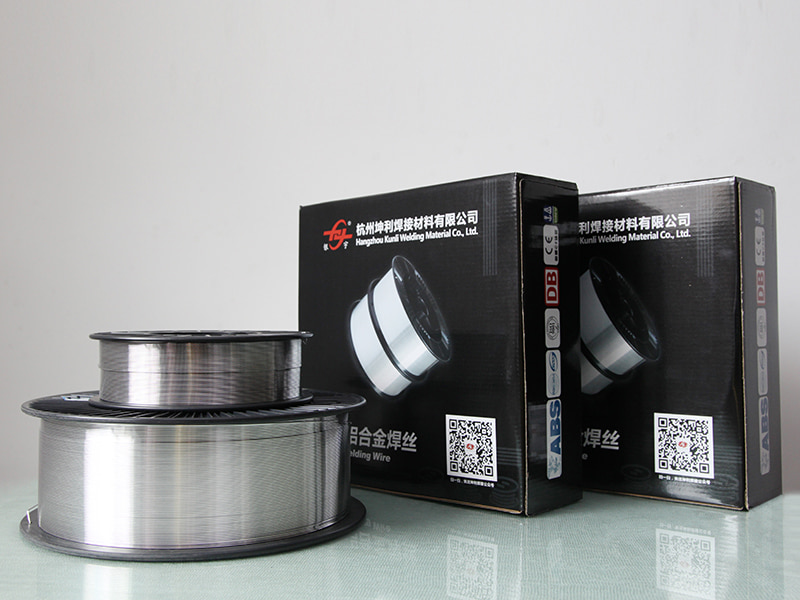

Aluminum Welding Wire

ER1100 Aluminum Welding Wire

1100 is about 99% pure Aluminum filler metal, which has excellent processability, higher corrosion resistance and tenacity, for welding 1000 series alloy metal mainly. Because of the soft performance, the feed status should be careful in MIG welding.

Mainly apply to high voltage bus, distribution box, heat exchanger, chemical and food etc.

ER1100 aluminum alloy welding wire is a high-purity aluminum welding material with an aluminum content of ≥99.0%, which has excellent corrosion resistance, high electrical conductivity and thermal conductivity. It is a non-heat-treatable alloy suitable for welding thin plates, heat exchangers, food processing equipment, etc., and is widely used in power, construction, automobile, refrigeration and other industries.

Product Features

High purity: aluminum content ≥99.0%, stable chemical composition.

Strong corrosion resistance: good resistance to chemical corrosion and atmospheric corrosion.

Good welding performance: stable arc, less spatter, and beautiful weld formation.

High machinability: suitable for thin plate welding, not easy to burn through.

Application field

Power industry: used for welding of electrolytic aluminum production equipment.

Food industry: welding food processing equipment to ensure cleanliness and safety.

Building decoration: welding aluminum alloy decorative parts.

Automobile manufacturing: welding lightweight aluminum alloy parts.

Refrigeration industry: welding heat exchangers.

Recommended welding method

TIG welding: use pure argon protection.

MIG welding: suitable for thin plate welding.

ER1100 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

-

General-Purpose vs Structural Aluminum Welding Wire Gui...

Feb 04, 2026

Selecting the right aluminum welding wire starts with grasping how its alloy makeup affects everything from how it flows...

-

Aluminum Welding Wire ER5356: Marine & Auto — Why It Wo...

Feb 02, 2026

Repair facilities that fix damaged boats, offshore gear, or automotive frames have to think past the quick patch job. Th...

-

Your Complete Guide to Aluminum Braided Wire Explained

Jan 30, 2026

When electrical connections need to flex, resist vibration, or distribute current across irregular surfaces, engineers i...

Industry Information Extension

More Information About ER1100 Aluminum Welding Wire Suppliers

Automotive Lightweighting Trends: How ER1100 Aluminum Welding Wire Supports EV Battery Tray Welding

The push for electric vehicle (EV) lightweighting has made high-purity aluminum welding a critical process in manufacturing. Among the top filler metals for this application, ER1100 aluminum welding wire stands out due to its 99% minimum aluminum content, making it ideal for joining 1060, 1070, and 1100 aluminum alloys—common materials in EV battery enclosures and trays.

Why ER1100 is the Preferred Choice for EV Battery Trays?

Unlike ER4043 or ER5356 aluminum filler wires, which contain silicon or magnesium, ER1100 TIG and MIG welding wire offers superior corrosion resistance and electrical conductivity—key factors for battery tray durability. Additionally, its low melting point (1,220°F/660°C) and excellent weldability minimize heat distortion, crucial for thin aluminum sheets used in lightweight EV structures.

Key Advantages of ER1100 in EV Manufacturing

High Ductility & Formability: Ensures crack-free welds in deep-drawn aluminum battery housings.

Minimal Intermetallic Formation: Unlike silicon-based wires (e.g., ER4043 filler metal), ER1100 reduces brittleness in welds.

Compliance with AWS A5.10 Standards: Meets stringent automotive welding specifications for safety-critical components.

Performance Comparison: ER1100 vs. Other Aluminum Filler Wires

| Parameter | ER1100 | ER4043 | ER5356 |

|---|---|---|---|

| Aluminum Content | 99%+ | 92-95% | 93-96% |

| Tensile Strength | 13 ksi | 24 ksi | 30 ksi |

| Best For | Pure Al alloys (1060, 1100) | 6xxx series (6061) | 5xxx series (5052, 5083) |

| Corrosion Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Electrical Conductivity | Excellent | Good | Moderate |

| Typical Applications | EV battery trays, chemical tanks | Structural automotive parts | Marine applications |

Emerging Trends: ER1100 in Next-Gen Battery Trays

With automakers like Tesla and BYD adopting ultra-light battery designs, demand for low-porosity aluminum welding wire is rising. ER1100’s compatibility with pulsed MIG welding and automated robotic welding systems makes it a cost-effective solution for high-volume EV production.