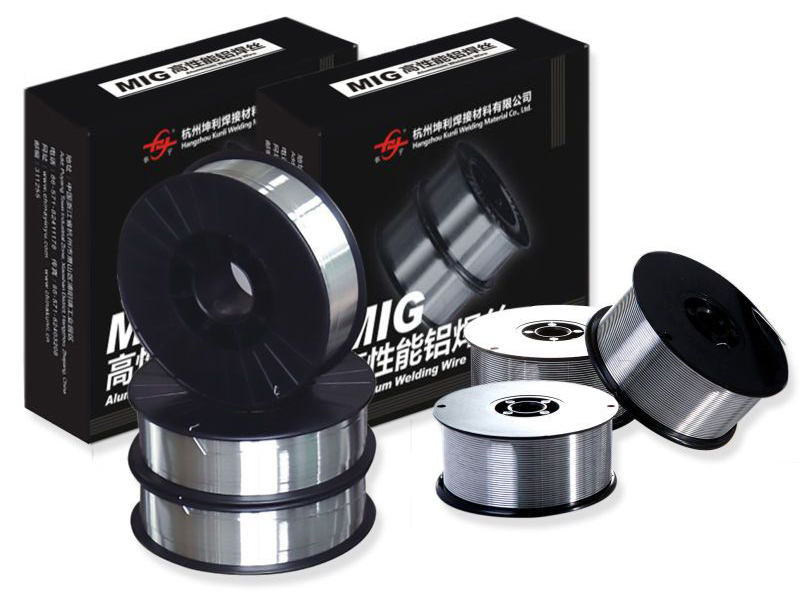

Aluminum Welding Wire

Aluminum Welding Wire ER5183

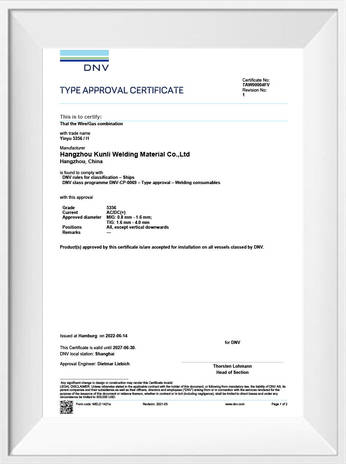

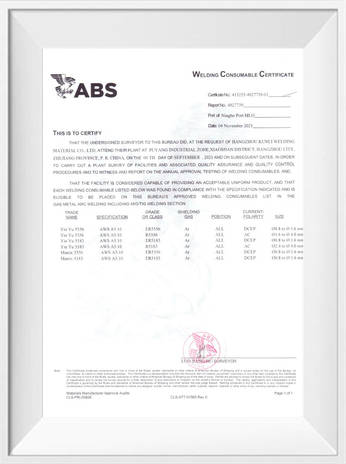

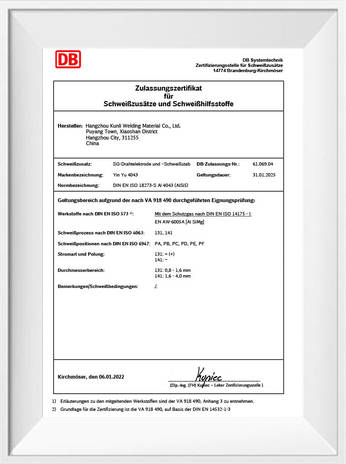

ER5183 is about 4.5% Magnesium Aluminum filler metal which has high strength, great seawater corrosion resistance, better bending property and high fracture toughness, recommended for welding the construction of parts of 5000 series, 6000 series,7000 series, such as 5083, 6061,6063, 5086, 7005, 7020 etc.; mainly apply to the construction of ship, off-shore facilities, cryogenic workshop, pressure vessel, rail transportation and automotive industries.

Aluminum Welding Wire ER5183 - Precision Alloy for Aluminum Joining

Product Features

- Alloy Composition: Contains precise aluminum-magnesium formulation optimized for MIG and TIG welding processes.

- Welding Performance: Provides controlled arc stability and reduced spatter during aluminum welding operations.

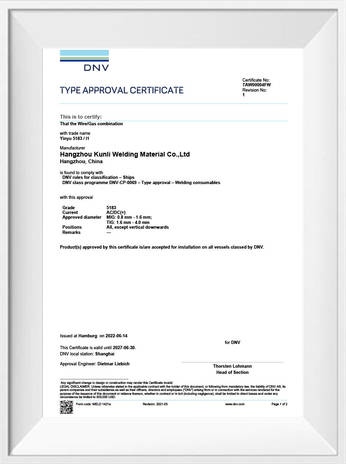

- Corrosion Resistance: Exhibits enhanced resistance to oxidation and environmental corrosion in marine and industrial applications.

Product Description

The Aluminum Welding Wire ER5183 is engineered for joining aluminum alloys with a focus on structural integrity and mechanical stability. It facilitates reliable fusion in MIG and TIG welding systems, addressing challenges such as porosity and inconsistent penetration in aluminum sheet and plate welding.

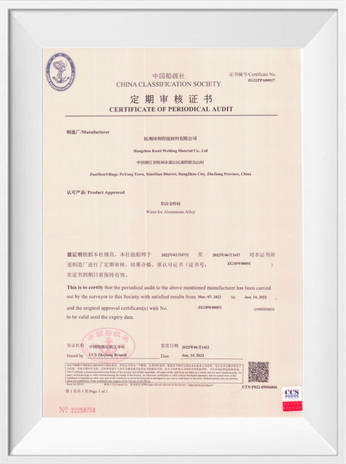

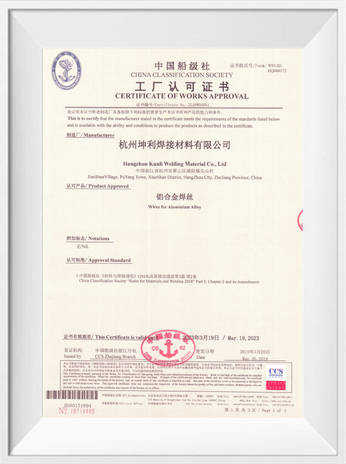

Manufactured in accordance with AWS A5.10/A5.10M standards, ER5183 welding wire is subjected to rigorous quality control and metallurgical testing to ensure uniform chemical composition, mechanical properties, and dimensional accuracy. Its consistent performance supports industrial applications requiring stringent technical compliance.

Technical Specifications

| Parameter | Value | Unit |

| Diameter | 1.2 / 1.6 | mm |

| Alloy Type | ER5183 | - |

| Material Form | Wire Spool | - |

| Melting Point | 580 | °C |

| Tensile Strength | 230-260 | MPa |

| Elongation | 10-12 | % |

Application Areas

This product is suitable for the following industrial scenarios:

- Marine and shipbuilding aluminum structures

- Automotive and transport vehicle body panels

- Aerospace structural components requiring corrosion-resistant welds

- General fabrication of aluminum storage tanks and piping

FAQ

1. What aluminum alloys can ER5183 welding wire be used with?

ER5183 wire is compatible with 5xxx series aluminum alloys, particularly those with magnesium content, including 5083, 5356, and 5754. It is optimized for structural welding where corrosion resistance is critical.

2. What welding processes are recommended for ER5183 wire?

This wire is suitable for Gas Metal Arc Welding (GMAW/MIG) and Gas Tungsten Arc Welding (GTAW/TIG). Proper shielding gas, typically pure argon or argon-helium mixtures, ensures stable arc and minimal porosity.

3. How does ER5183 compare in corrosion resistance and mechanical properties?

ER5183 demonstrates higher corrosion resistance than ER5356 in marine environments while maintaining tensile strength and elongation suitable for structural applications. It provides a balance between weldability and long-term durability in harsh conditions.

Aluminum Welding Wire ER5183

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Why Choose Kunli TIG Welding for Precision and Control

Mar 02, 2026

Walk into most working fabrication shops today and you will notice something: welders who built their careers on wire-fe...

-

Why Do Aluminum Welds Keep Cracking — And What You're O...

Feb 27, 2026

Every joining operation in Aluminum fabrication requires thoughtful decision-making that influences the final component ...

-

Key Factors to Choose the Right Aluminum Filler Metal

Feb 23, 2026

When fabricators face a choice between filler materials for joining nonferrous metals, they often underestimate how prof...

-

Common Mistakes to Avoid When Using Aluminum Welding Wi...

Feb 20, 2026

Every fabrication shop has experienced the frustration of Aluminum welds failing inspection after hours of careful work....

Industry Information Extension

More Information About Aluminum Welding Wire ER5183 Suppliers

How Aluminum Mig Wire Manufacturers optimize the MIG process parameters of ER5183?

1. Matching of welding current and voltage

Current (wire feeding speed):

ER5183 is an aluminum-magnesium alloy welding wire. Pulse MIG (AC) or conventional DC reverse connection (DCEP) is recommended. The current range is usually 120~300A (adjusted according to the plate thickness).

Thin plate (1~3mm): low current (120~180A) to avoid burn-through.

Medium and thick plate (4~12mm): medium and high current (200~300A) to ensure penetration.

Voltage: needs to be adjusted in coordination with current to avoid spatter or unfusion:

Typical range 18~24V. Too high voltage can easily lead to wide and shallow welds, while too low voltage will lead to insufficient penetration.

Optimization method: Adjust to uniform weld formation and no undercut through trial welding + macroscopic metallographic detection.

2. Shielding gas selection and flow

Gas type:

Pure argon (Ar): suitable for thin plates, stable arc, less spatter.

Argon-helium mixture (Ar+30~50% He): used for medium and thick plates to increase heat input and penetration.

Gas flow:

15~25 L/min, too low flow can easily lead to pores, too high flow may disrupt the arc.

Note: Ensure that the gas purity is ≥99.99% to avoid moisture and impurities (such as N₂, O₂) causing pores.

3. Wire feeding speed and welding gun angle

Wire feeding speed:

positively correlated with current, usually 5~12 m/min, needs to match the dynamic response of the welding machine.

Welding gun angle:

Push welding method (10°~15° inclination): recommended for aluminum welding to reduce the risk of pores.

Keep a short arc length (1~3mm) to avoid magnesium burnout.

4. Preparation and post-processing before welding

Cleaning: Use a stainless steel brush or acetone to remove the oxide film (Al₂O₃) on the surface of the base material and welding wire.

Preheating: Thick plates (>6mm) can be preheated to 80~120℃ to reduce thermal stress.

Interlayer temperature control: ≤150℃ to avoid intergranular corrosion.

5. Process verification method

Macroscopic inspection: Observe whether the weld section is fully melted and defect-free.

Mechanical test: Tensile/bending test to verify joint strength (ER5183 weld strength is usually ≥275MPa).

X-ray flaw detection: Detect internal pores or cracks. These optimization and verification practices are widely adopted by aluminum welding wire manufacturers to ensure stable performance and reliable weld quality.