Aluminum Welding Wire

ER5556 Aluminum Welding Wire

Comparing with 5356, 5556 has more Magnesium and Manganese, which has higher strength, better tenacity, higher corrosion resistance and better welding performance, recommended for welding alloy of 5000 series, 6000 series, 7000 series, such as 5050, 5052, 5083, 5456, 6005A, 6061,6063,6082,7005 etc..

ER5556 aluminum alloy welding wire is a high-performance aluminum-magnesium alloy welding material, widely used in the welding of high-strength aluminum alloys. The welding wire contains 5% magnesium and 0.8% manganese, as well as a small amount of chromium and titanium, with high strength, good corrosion resistance and thermal cracking resistance. The weld can still remain white after anodizing, providing good color matching for the welded joint.

Product Features

Physical properties:

Density: 2.65-2.66 g/cm³

Melting temperature: 570℃-635℃

Tensile strength: 280-310 MPa

Elongation: ≥16%

Welding process:

Applicable gas: argon, helium or argon-helium mixed gas

Applicable welding method: MIG, TIG

Application field

ER5556 aluminum alloy welding wire is suitable for welding of 5000 series high-strength aluminum alloys, and is widely used in the following fields:

Aerospace: used for aircraft structural parts, engine components, etc.

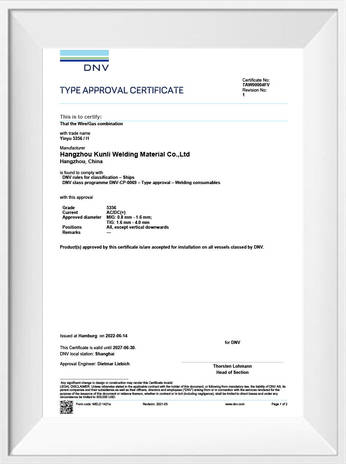

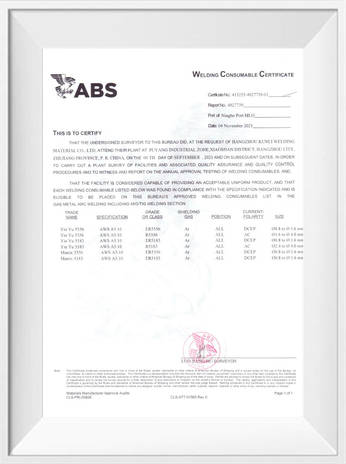

Shipbuilding: welding hull structure, marine engineering equipment.

Automotive industry: used for welding of automotive parts.

Chemical and food industries: welding of storage tanks, pipelines, etc.

Electric power and machinery manufacturing: used for welding of generators, motors and other equipment.

Precautions

It is not suitable for aluminum alloy structures with working temperatures exceeding 65°C to avoid stress corrosion cracking.

Before welding, the oxides and oil stains on the surface of the workpiece must be strictly removed to prevent weld defects.

During welding, a pad can be used to support the molten metal to ensure the formation of the weld.

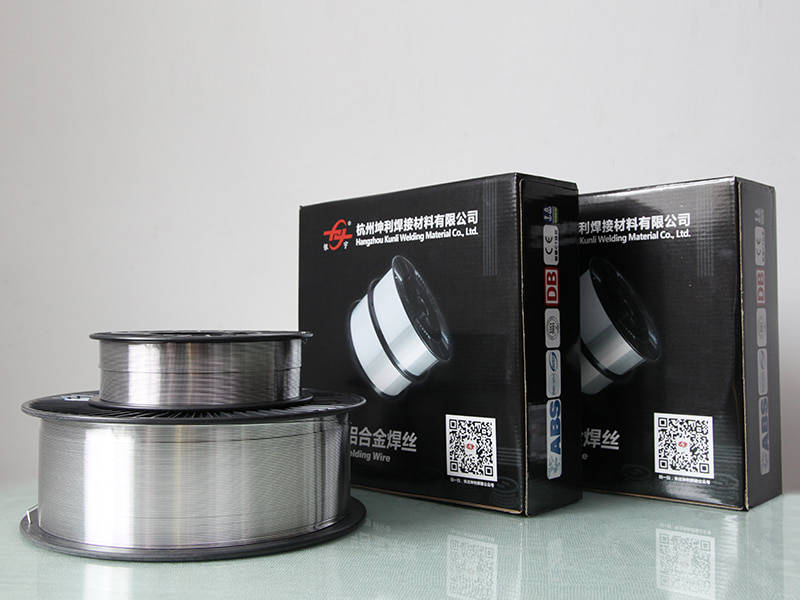

ER5556 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Aluminum Welding Wire ER5356: Marine & Auto — Why It Wo...

Feb 02, 2026

Repair facilities that fix damaged boats, offshore gear, or automotive frames have to think past the quick patch job. Th...

-

Your Complete Guide to Aluminum Braided Wire Explained

Jan 30, 2026

When electrical connections need to flex, resist vibration, or distribute current across irregular surfaces, engineers i...

-

How Wire Cast and Helix Influence MIG Weld Feed Stabili...

Jan 23, 2026

Welding professionals working with aluminum face unique challenges that their steel welding counterparts rarely encounte...

-

How Does the Silicon Content in alloy er4043 Affect Pos...

Jan 28, 2026

In the field of high-precision aluminum fabrication, achieving a seamless aesthetic finish after welding is often as cri...

Industry Information Extension

More Information About ER5556 Aluminum Welding Wire Suppliers

How to Choose Between ER5356 vs. ER5556 Welding Wire for High-Strength Aluminum Projects

When working on high-strength aluminum projects, selecting the right aluminum welding wire is crucial for achieving strong, crack-free welds. Two of the most commonly used wires are ER5356 and ER5556, each with distinct properties that make them suitable for different applications.

Key Differences Between ER5356 and ER5556 Aluminum Welding Wire

1. Chemical Composition & Mechanical Properties

The primary difference between ER5356 and ER5556 welding wire lies in their alloy composition:

| Property | ER5356 | ER5556 |

|---|---|---|

| Aluminum (Al) | ≈94.5% | ≈93.5% |

| Magnesium (Mg) | 4.5-5.5% | 4.7-5.5% |

| Manganese (Mn) | 0.05-0.20% | 0.5-1.0% |

| Tensile Strength | ≈38,000 psi (262 MPa) | ≈42,000 psi (290 MPa) |

| Yield Strength | ≈19,000 psi (131 MPa) | ≈24,000 psi (165 MPa) |

The higher manganese content in ER5556 welding wire improves its strength and workability, making it ideal for structural aluminum welding where higher load-bearing capacity is required.

2. Best Applications for Each Wire

ER5356 is widely used for welding 5xxx series aluminum alloys, particularly in marine applications, automotive panels, and general fabrication where moderate strength and good corrosion resistance are needed.

ER5556, with its superior strength, is preferred for heavy-duty aluminum welding, such as military vehicles, aerospace components, and offshore structures where fatigue resistance is critical.

3. Weldability & Crack Resistance

While both wires offer good aluminum MIG welding performance, ER5556 filler wire is less prone to hot cracking due to its refined grain structure. This makes it a better choice for thick aluminum plate welding or projects requiring multiple passes.

4. Corrosion Resistance in Saltwater Environments

For marine-grade aluminum welding, ER5356 is often chosen due to its excellent saltwater corrosion resistance. However, ER5556 performs well in harsh environments where higher mechanical stress is involved, such as shipbuilding and offshore platforms.

Which Wire Should You Choose?

For high-strength, structural welds → ER5556 aluminum welding wire (better for military, aerospace, and load-bearing structures).

For general fabrication and marine use → ER5356 welding wire (more cost-effective and easier to weld).