Aluminum Welding Wire

ER5154 Al-Mg Alloy Wire

Grade 5154, Al-Mg alloy wire is used for braiding in coaxial cable for shielding, with it's good performance.

Main Application: flexible coaxial cable, a variety of audio and video cable, vehicle signal cable, network cable, data transmission cable and so on.

ER5154 Al-Mg Alloy Wire - Corrosion-Resistant Aluminum-Magnesium Wire for Industrial Fabrication

Product Features

- Corrosion Resistance: Engineered with aluminum-magnesium composition to resist oxidation and maintain structural integrity in marine and industrial environments.

- Weldability: Optimized for gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) processes, ensuring stable weld pools and minimal porosity.

- Mechanical Strength: Maintains tensile and yield strength suitable for structural applications in lightweight fabrication and sheet metal assembly.

Product Description

The ER5154 Al-Mg Alloy Wire is designed for precision welding of aluminum-magnesium alloys commonly used in shipbuilding, pressure vessels, and automotive body panels. Its chemical composition ensures a balance between corrosion resistance and mechanical performance, supporting long-term structural reliability.

Manufactured according to ASTM B535 standards, the wire undergoes strict quality control procedures including chemical composition verification and dimensional consistency checks. Its compatibility with automated and manual welding systems allows integration into industrial fabrication workflows with predictable outcomes.

Technical Specifications

| Diameter | 0.8 mm / 1.0 mm / 1.2 mm |

| Chemical Composition (wt%) | Al balance, Mg 4.5–5.5, Mn 0.5–1.0, Si ≤0.25, Fe ≤0.4 |

| Tensile Strength | 260–310 MPa |

| Yield Strength | 110–160 MPa |

| Elongation | 12–20% |

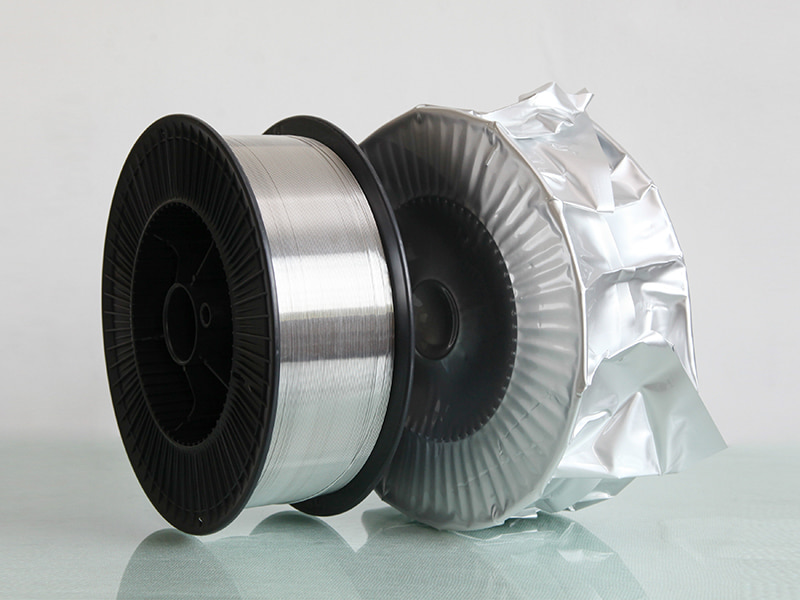

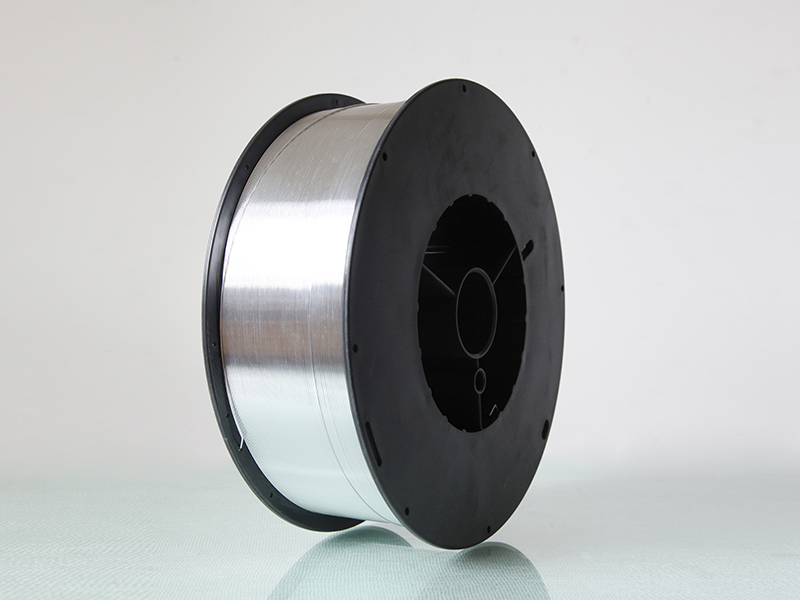

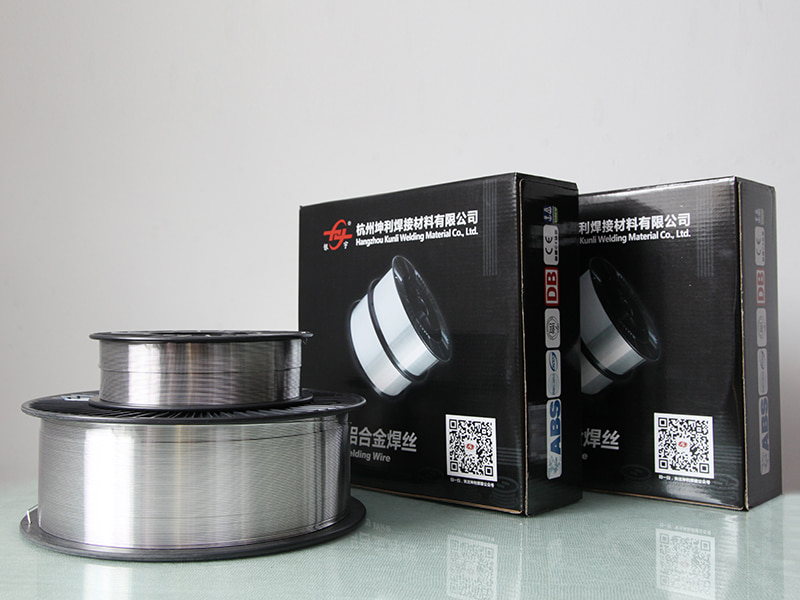

| Wire Form | Spool or coil, standard packaging 15–25 kg |

Applications

This product is suitable for the following industrial scenarios:

- Marine and shipbuilding structures requiring high corrosion resistance

- Pressure vessels and storage tanks fabricated from aluminum-magnesium alloys

- Automotive and aerospace components demanding lightweight yet durable welds

FAQ

What welding processes are compatible with ER5154 Al-Mg Alloy Wire?

ER5154 wire is compatible with gas tungsten arc welding (GTAW/TIG) and gas metal arc welding (GMAW/MIG). It produces stable welds with minimal porosity and is suitable for both manual and automated welding operations.

How does ER5154 perform in marine environments?

The wire’s aluminum-magnesium composition provides enhanced corrosion resistance against saltwater exposure. It maintains structural integrity and prevents pitting or intergranular corrosion in marine applications when proper welding procedures are followed.

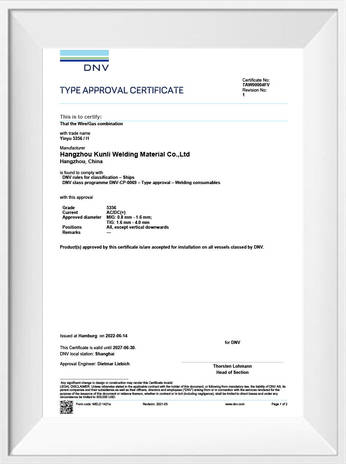

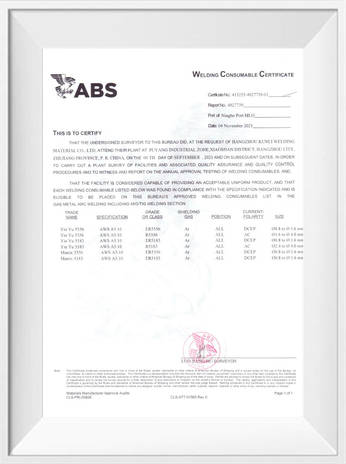

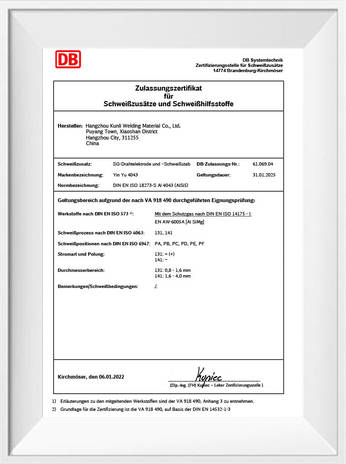

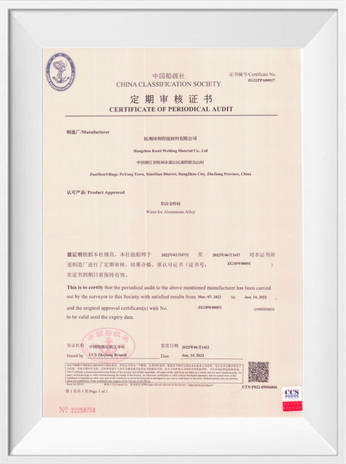

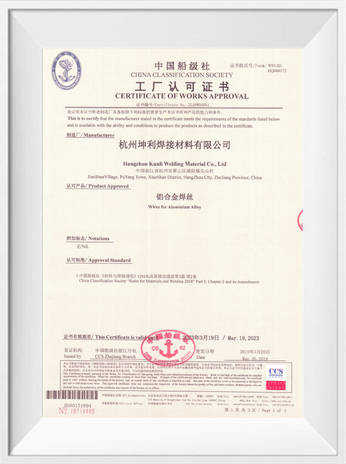

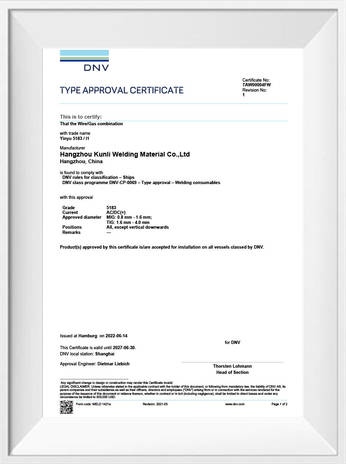

What standards and certifications does ER5154 comply with?

ER5154 is manufactured in accordance with ASTM B535 and meets chemical composition and mechanical property requirements for aluminum-magnesium welding consumables. Batch testing ensures compliance with industry standards for tensile strength, yield strength, and elongation.

ER5154 Al-Mg Alloy Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

How Does the Low Melting Point of ER4047 Welding Wire M...

Feb 13, 2026

Precision welding of thin-gauge aluminum requires a delicate balance between achieving structural fusion and managing th...

-

What is the Maximum Service Temperature for Components ...

Feb 11, 2026

In the field of cryogenic and structural aluminum fabrication, alloy er4043 (Al-Si5) is the most widely utilized filler ...

-

Does Using ER5183 Welding Wire Significantly Improve th...

Feb 09, 2026

In the field of high-performance metallurgy, selecting the appropriate filler metal is paramount for ensuring the struct...

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

Industry Information Extension

More Information About ER5154 Al-Mg Alloy Wire Suppliers

Application of ER5154 aluminum-magnesium alloy welding wire in shipbuilding and welding process optimization

1. Core requirements of shipbuilding for ER5154 welding wire

Material matching:

ER5154 (Al-Mg3.1-3.9%) is compatible with the composition of marine 5083/5086 aluminum alloy parent materials to avoid electrochemical corrosion.

Performance advantages:

High resistance to seawater corrosion (Mg element forms a dense oxide film), low density (lightweight), good low-temperature toughness (applicable to polar ships).

2. Typical application scenarios and cases

Hull structure welding: MIG welding of decks, bulkheads, side plates and other parts.

Special parts: Low-temperature environment welding of liquefied natural gas (LNG) ship storage tanks.

Maintenance field: Repair welding of corrosion areas of magnesium and aluminum parts of the hull.

3. Analysis of welding process difficulties

Oxide film problem:

The Al₂O₃ film (melting point 2050℃) on the surface of aluminum-magnesium alloy leads to the tendency of unfusion, and high-purity argon protection (≥99.99%) is required.

Hot crack sensitivity:

High magnesium content is prone to solidification cracks, and heat input needs to be controlled (recommendation: 80-120A, 20-25V).

Porosity defect:

Sudden change in hydrogen solubility causes pores, and strict cleaning is required before welding (acetone degreasing + stainless steel wire brush treatment).

4. Key measures for process optimization

Parameter optimization:

Pulse MIG welding: frequency 50-150Hz, base current 60A, peak current 180A, reduce heat input.

Multi-pass welding design: interlayer temperature is controlled below 100℃ (to avoid precipitation of Mg₂Si embrittled phase).

Equipment and consumables adaptation:

Use a push-pull wire feeder (such as Fronius push-pull gun), the inner diameter of the conductive nozzle ≥ 1.5 times the diameter of the welding wire.

Protection gas ratio: Ar + 30% He improves arc stability (suitable for thick plate welding).

Quality control:

Non-destructive testing: X-ray flaw detection (porosity ≤ 3%), penetration testing (surface cracks).

5. Comparison of actual application effects

Case data: After a shipyard adopts the optimized process:

Welding efficiency increased by 25% (single-pass welding speed reached 50cm/min);

Weld tensile strength ≥ 290MPa (reaching more than 90% of the parent material);

Salt spray test for 500 hours without pitting (in line with DNV-GL standards).