Aluminum Welding Wire

ER4047 Aluminum Mig Welding Wire

4047 is a 12% Silicon Aluminum filler metal which has excellent corrosion resistance and low melting point ensuring a very low number of deformations in the parent metal, recommended for welding alloys as 1060, 1350, 3003, 3004, 5052, 6060,6061,6063,etc. and casting Al alloys, such as 710.0,711.0.

ER4047 Aluminum Mig Welding Wire - Precision Aluminum Joining for Automotive and Structural Applications

Product Features

- Composition Stability: Contains approximately 12% silicon, designed to minimize weld cracking and reduce thermal distortion during aluminum MIG welding.

- Arc Performance: Provides consistent arc stability and smooth metal transfer, facilitating controlled bead formation in various aluminum alloys.

- Corrosion Resistance: Suitable for applications requiring resistance to atmospheric and chemical corrosion due to its alloy composition.

Product Description

The ER4047 Aluminum MIG Welding Wire is engineered for joining aluminum components where reduced thermal expansion and crack resistance are critical. Its silicon-enriched composition enables welding of aluminum alloys such as 4xxx and 6xxx series with controlled fluidity and minimal porosity.

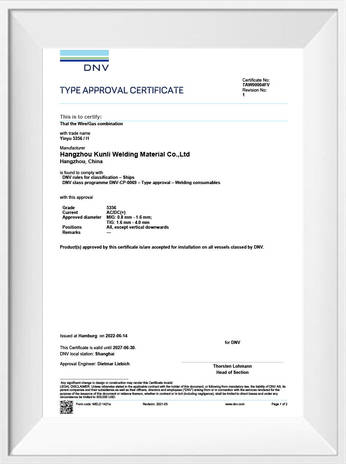

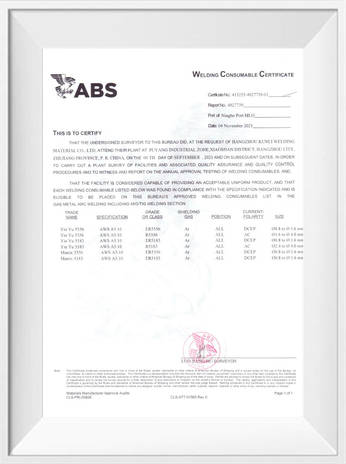

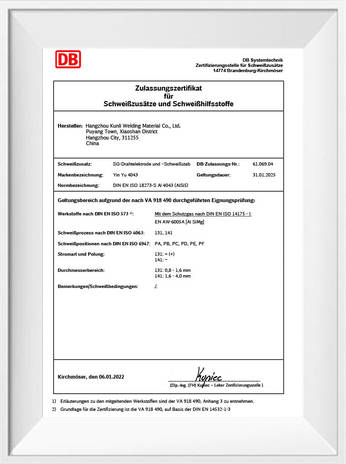

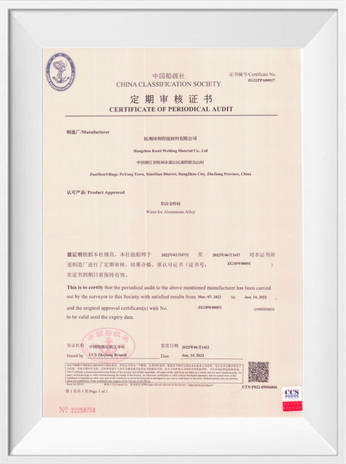

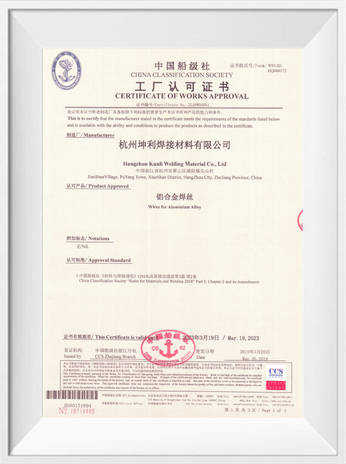

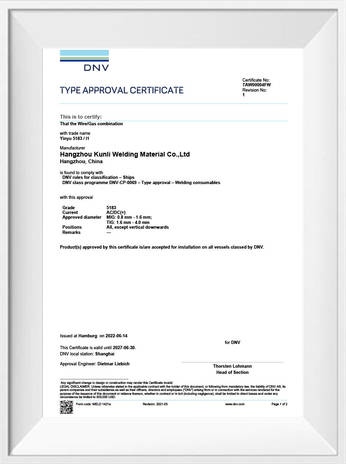

Manufactured under ISO 9001-certified processes, this welding wire conforms to AWS A5.10/A5.10M standards. The consistent chemical composition and mechanical properties ensure reliable performance in automotive body panels, heat exchangers, and structural frameworks.

Technical Specifications

| Specification | Value |

| Alloy Type | ER4047 |

| Diameter | 0.8mm, 1.0mm, 1.2mm |

| Silicon Content | 11.0-13.0% |

| Tensile Strength | 150-180 MPa |

| Elongation | 8-12% |

| Welding Position | Flat, Horizontal, Vertical |

| Recommended Shielding Gas | 100% Argon |

| Compliance Standard | AWS A5.10/A5.10M |

Applications

This product is suitable for the following industrial scenarios:

- Automotive body panel welding requiring dimensional stability.

- Heat exchanger and radiator fabrication.

- Structural aluminum assembly in architectural or transportation sectors.

FAQ

1. Can ER4047 wire be used for welding 6xxx series aluminum alloys?

Yes, ER4047 is compatible with 6xxx series aluminum for MIG welding, particularly where reduced thermal expansion and crack resistance are needed. Preheating may be required for thicker sections to prevent porosity.

2. What shielding gas is recommended for ER4047 MIG welding?

100% Argon is recommended to ensure stable arc performance and optimal weld bead formation. Mixed gases are generally not necessary for standard ER4047 applications.

3. What is the typical application thickness range for ER4047 welding wire?

ER4047 is effective for aluminum sheet and plate thicknesses from 1 mm up to 6 mm. For thicker sections, controlled heat input and multiple passes are advised to minimize distortion and maintain weld integrity.

ER4047 Aluminum Mig Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Does Using ER5183 Welding Wire Significantly Improve th...

Feb 07, 2026

In the field of high-performance metallurgy, selecting the appropriate filler metal is paramount for ensuring the struct...

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

-

General-Purpose vs Structural Aluminum Welding Wire Gui...

Feb 04, 2026

Selecting the right aluminum welding wire starts with grasping how its alloy makeup affects everything from how it flows...

-

Aluminum Welding Wire ER5356: Marine & Auto — Why It Wo...

Feb 02, 2026

Repair facilities that fix damaged boats, offshore gear, or automotive frames have to think past the quick patch job. Th...

Industry Information Extension

More Information About ER4047 Aluminum Mig Welding Wire Suppliers

How to optimize MIG welding parameters for ER4047 wire? A guide to current, gas and speed

ER4047 (aluminum-silicon alloy, containing 12% silicon) is widely used in thin plate welding, automotive parts and refrigeration industries due to its excellent fluidity, crack resistance and heat resistance. However, aluminum welding is parameter-sensitive and requires balancing key factors such as current, gas and wire feed speed. The following is a practical guide to optimizing MIG welding parameters:

1. Shielding gas selection

Recommended gas: pure argon (Argon 100%).

Argon can stabilize the arc and reduce oxidation, making it suitable for aluminum welding;

Avoid using mixed gases containing helium (He) (such as Ar/He) unless higher penetration is required (but ER4047 is mostly used for thin plates and usually does not require additional penetration).

Gas flow: 15–25 CFH (7–12 L/min), ensuring coverage of the welding area and avoiding pores.

2. Current and voltage settings

Polarity: DC reverse connection (DCEP), ensuring cathode cleaning and breaking the oxide film on the aluminum surface.

Parameter reference (according to plate thickness):

| Thickness (mm) | Current (A) | Voltage (V) | Wire Feed Speed (m/min) |

|---|---|---|---|

| 0.8–1.6 | 70–100 | 16–18 | 4–6 |

| 1.6–3.2 | 100–150 | 18–20 | 6–8 |

| 3.2–6.0 | 150–220 | 20–24 | 8–12 |

Thin plate skills: reduce current (avoid burn-through) and increase welding speed;

Thick plate skills: appropriate preheating (100–150°C) to reduce thermal stress.

3. Wire feeding speed and welding gun angle

Wire feeding speed: needs to match the current. Too fast will easily cause spatter, and too slow will cause poor fusion;

Recommended starting value: 6 m/min, fine-tuned according to weld formation.

Welding gun angle: push welding method (10°–15° tilt) to improve gas shielding effect.

4. Welding speed and heat input control

Thin plate (<3mm): high-speed welding (30–50 cm/min) to reduce heat accumulation;

Thick plate: appropriately reduce speed (20–30 cm/min) to ensure penetration.

Key point: maintain uniform speed and avoid pauses (aluminum conducts heat quickly and is prone to forming concave or nodular welds).

5. Common problems and solutions

Porosity: Check gas purity (≥99.99%), clean the base material (remove oil/oxide film);

Unfused: Increase current or reduce welding speed;

Cracks: Control interlayer temperature (≤150°C) to avoid silicon segregation.