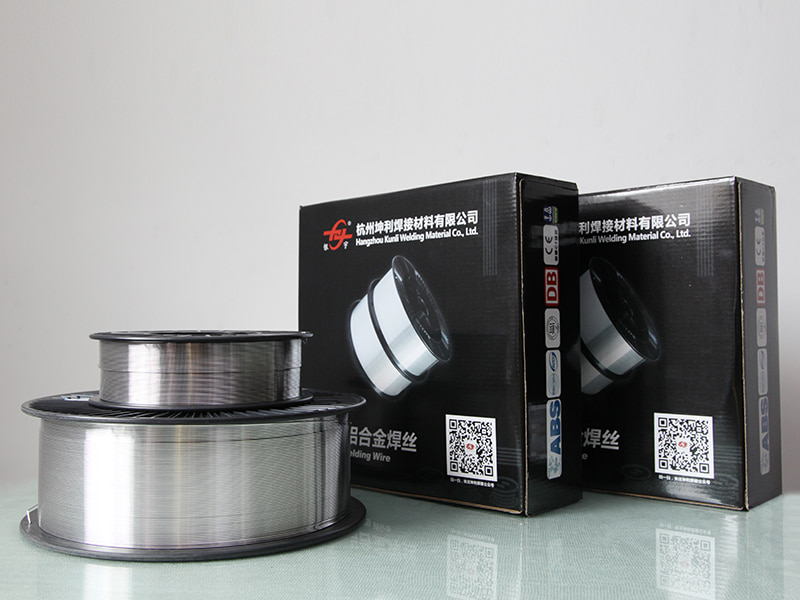

Aluminum Welding Wire

ER5754 Aluminum Welding Wire

5754 is about 3% Magnesium Aluminum filler metal which has medium strength, better seawater corrosion resistance, recommended for welding the construction of parts of 5000 series, 6000 series, such as 5083, 6061,6063, 5086 etc.;

ER5754 aluminum alloy welding wire is a high-performance filler material designed for welding 5xxx series aluminum alloys (such as 5083, 5754, etc.), which complies with the American Welding Society (AWS) A5.10 standard. Its chemical composition is highly matched with the parent material, and it has excellent corrosion resistance and welding processability. It is widely used in shipbuilding, marine engineering, chemical containers and other fields.

Core characteristics

Chemical composition optimization

Magnesium content: 3.0%-3.8% (typical value), ensuring that the strength and corrosion resistance of the weld are consistent with the parent material.

Low iron, low silicon: reduce the negative impact of impurities on weld toughness and avoid thermal cracking tendency.

Mechanical properties

Tensile strength: ≥280 MPa (specific value adjusted according to process).

Elongation: ≥12% (to ensure weld plasticity).

Hardness: HB 80-100, balancing strength and processability.

Corrosion resistance

The weld is resistant to seawater and industrial atmospheric corrosion and is suitable for harsh environments.

Verified by salt spray test (such as ASTM B117), the corrosion rate is less than 5% of the parent material.

Welding processability

Stable arc: less spatter under DC reverse connection (DCEN), beautiful weld formation.

Good molten pool fluidity: suitable for all-position welding (flat welding, vertical welding, overhead welding).

Application scenarios

Shipbuilding

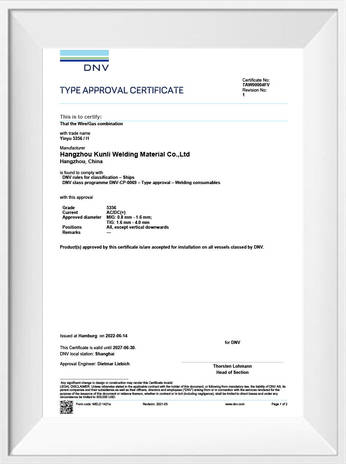

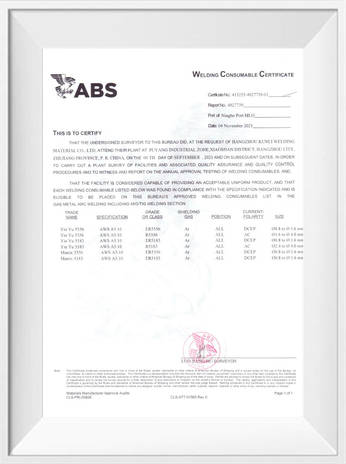

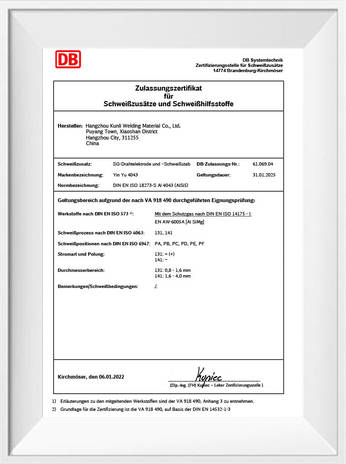

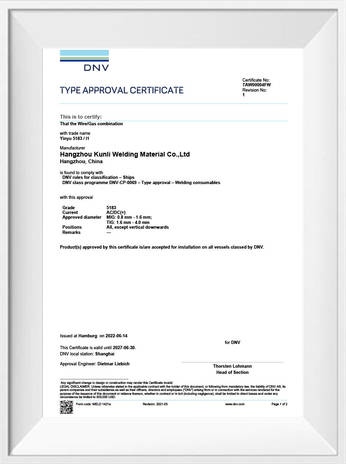

Hull structure, deck, bulkhead welding, meet the certification requirements of classification societies such as DNV and ABS.

Typical cases: aluminum alloy yacht hull splicing, LNG tanker liquid cargo tank sealing welding.

Marine engineering

Offshore platform, oil storage tank, seawater pipeline welding, resist seawater corrosion and stress corrosion cracking.

Chemical and food industry

Corrosion-resistant container and pipeline system welding, in accordance with FDA and ASME standards.

Transportation

High-speed train body and automobile lightweight structural parts welding, taking into account strength and weight reduction requirements.

Architecture and decoration

Aluminum alloy curtain wall, door and window frame welding, ensure smooth appearance and structural safety.

Recommendations for use

Pre-welding preparation

Clean the surface of the parent material (remove oil and oxide film), and make a groove (V-shaped or U-shaped).

Preheat thick plates (>25mm) to 100-150℃ to reduce the risk of thermal cracks.

Welding parameter optimization

Use pulse MIG welding (if necessary) to improve the welding quality of thin plates.

Control the interlayer temperature ≤150℃ to avoid coarse grains.

Post-weld treatment

Grind the weld excess height to the same level as the parent material, and perform X-ray or ultrasonic flaw detection (according to the standard).

Perform stress relief heat treatment if necessary (such as T6 state parent material).

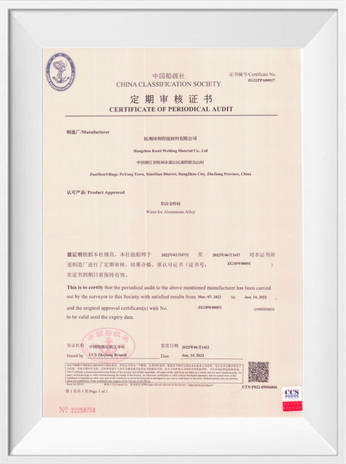

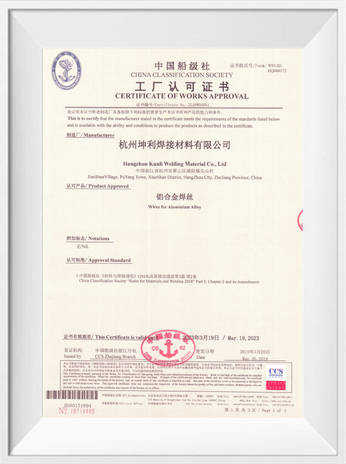

Quality certification and standards

Comply with international standards such as AWS A5.10, ISO 18273, EN ISO 14175, etc.

Provide material certification (MTC) and third-party test reports (such as SGS, TÜV).

ER5754 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

How Does the Low Melting Point of ER4047 Welding Wire M...

Feb 13, 2026

Precision welding of thin-gauge aluminum requires a delicate balance between achieving structural fusion and managing th...

-

What is the Maximum Service Temperature for Components ...

Feb 11, 2026

In the field of cryogenic and structural aluminum fabrication, alloy er4043 (Al-Si5) is the most widely utilized filler ...

-

Does Using ER5183 Welding Wire Significantly Improve th...

Feb 09, 2026

In the field of high-performance metallurgy, selecting the appropriate filler metal is paramount for ensuring the struct...

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

Industry Information Extension

More Information About ER5754 Aluminum Welding Wire Suppliers

ER5754 Aluminum Welding Wire in Electric Vehicle Battery Tray Manufacturing

The growing demand for lightweight and high-strength aluminum alloys in electric vehicle (EV) manufacturing has made ER5754 aluminum welding wire a critical material, particularly in battery tray fabrication. As automakers prioritize weight reduction to extend battery range, 5xxx series aluminum filler wires like ER5754 offer excellent corrosion resistance and weldability, making them ideal for marine-grade aluminum welding and automotive structural components.

Why ER5754 is Preferred for EV Battery Trays?

Compared to other aluminum welding wires for automotive applications, ER5754 stands out due to its:

High magnesium content (~3.1%), enhancing strength without heat treatment (non-heat-treatable alloy).

Superior corrosion resistance, crucial for battery enclosures exposed to harsh environments.

Low crack sensitivity, reducing defects in high-speed robotic welding processes.

A key competitor, ER5356 aluminum welding wire, is also popular but has slightly lower fatigue resistance in welded joints, making ER5754 a better choice for structural aluminum welding in EVs.

Optimizing ER5754 Welding Parameters for Battery Trays

To achieve high-quality welds in aluminum battery tray manufacturing, welding parameters must be carefully controlled:

| Parameter | Recommended Setting | Technical Consideration |

|---|---|---|

| Wire Diameter | 1.2mm – 1.6mm | Ideal for thick aluminum welding (3-8mm battery tray panels) |

| Shielding Gas | 100% Argon or Ar/He mix | Reduces porosity in marine-grade aluminum welds |

| Travel Speed | 30-50 cm/min | Prevents aluminum weld cracking in high-stress areas |

| Voltage | 19-23V | Optimal for pulse welding aluminum applications |

| Wire Feed Speed | 6-8 m/min | Balances deposition rate and weld bead appearance |

| Gas Flow Rate | 20-25 CFH | Critical for low-porosity aluminum welds |

Emerging Trends: ER5754 in Green Manufacturing

With sustainability becoming a priority, recyclable aluminum welding wire like ER5754 is gaining traction. Its compatibility with post-weld anodizing and eco-friendly welding processes makes it a future-proof choice for EV battery case welding.

For manufacturers looking for low-cost aluminum welding wire with high performance, ER5754 provides a balance between weld strength vs. ductility, making it a top pick in automotive and marine aluminum fabrication.