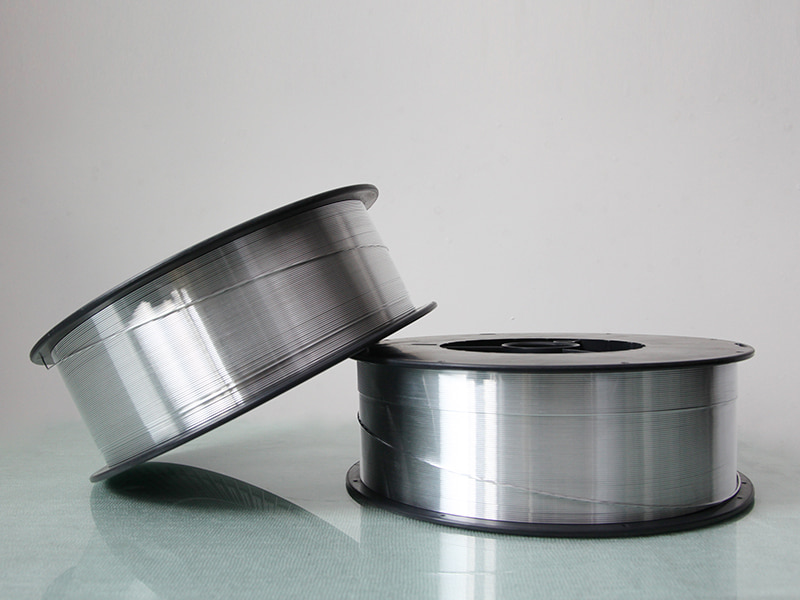

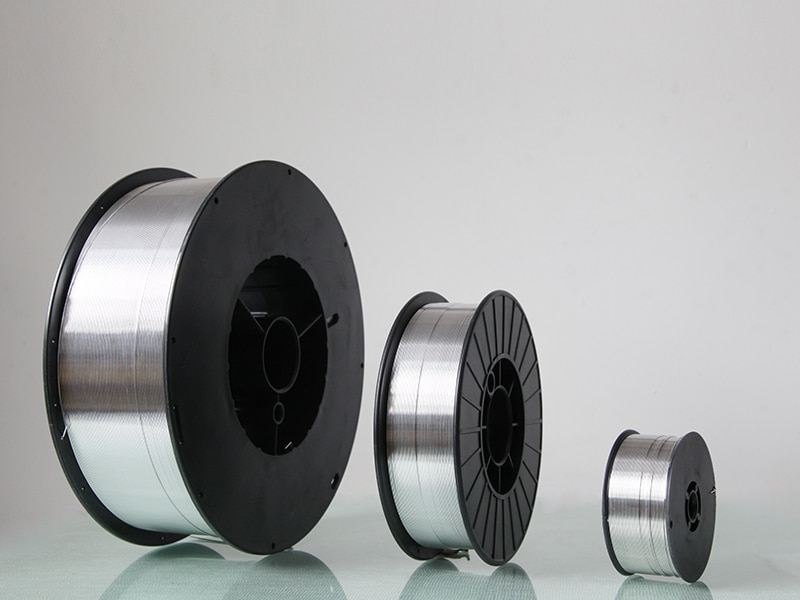

Aluminum Welding Wire

Aluminum Welding Wire ER5356

5356 is about 5% Magnesium Aluminum filler metal which has high strength, high corrosion resistance and matches the color well with the parent metal after anodizing, recommended for welding casting and forging Al-Mg alloys with <5% Magnesium and parts of wrought alloy of 5000 series, 6000 series, 7000 series, such as 5050, 5052, 5083, 5456, 6005A, 6061,6063,6082,7005 etc.

Aluminum Welding Wire ER5356 is a versatile and high-performance welding wire designed for a wide range of applications. Known for its exceptional strength, corrosion resistance, and reliability, this welding wire is ideal for industries where durability and high performance are essential. Kunli manufactures Aluminum Welding Wire ER5356 to the highest standards, ensuring optimal results for professionals in various sectors, including marine, automotive, and structural welding.

Typical Applications

Aluminum Welding Wire ER5356 is highly suitable for a wide range of industries where strength, reliability, and corrosion resistance are crucial. Some of the primary applications include:

- Marine Industry: Perfect for boat hulls, ships, and offshore structures that are exposed to saltwater and harsh environmental conditions.

- Automotive Industry: Used for automotive parts where high-strength, lightweight welding is needed.

- Structural Applications: Applied in the welding of aluminum frames, pressure vessels, storage tanks, and other structural components.

- Sports Equipment: Ideal for welding aluminum frames and components in sports gear that require both durability and resistance to corrosion.

- Compressed Containers: Commonly used in the welding of compressed containers where high-strength and pressure resistance are essential.

- Rail Transportation: ER5356 is used in rail transportation applications, ensuring the structural integrity of rail vehicles and components.

- Aerospace Industry: Suitable for aircraft and aerospace components requiring high-strength welds and corrosion resistance.

- General Welding: Suitable for general-purpose welding of aluminum alloys in both TIG and MIG welding processes.

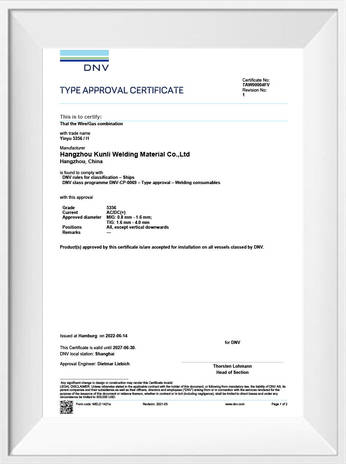

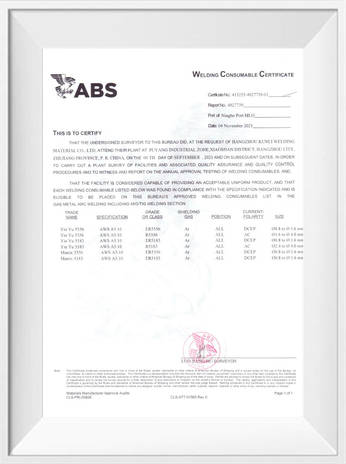

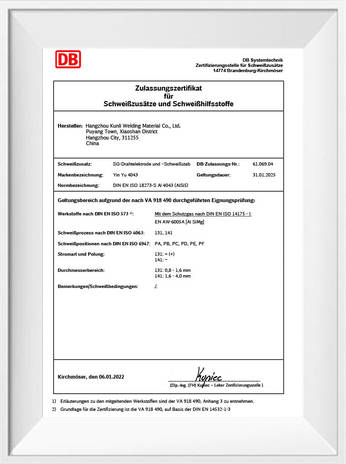

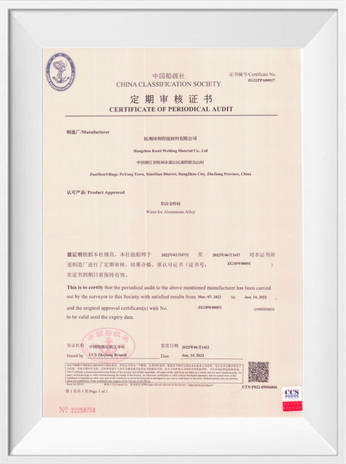

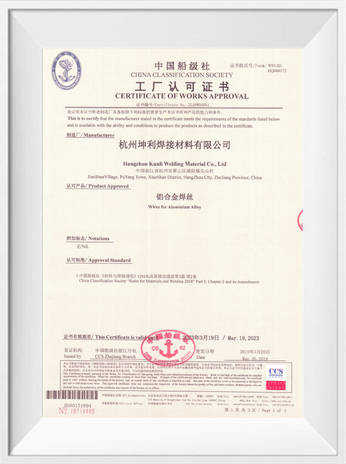

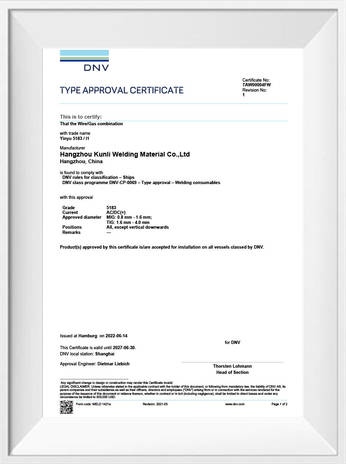

Certification and Quality Assurance

Kunli ensures that all of our Aluminum Welding Wire ER5356 products are certified and meet the highest industry standards. Our welding wire products are authenticated by:

- DB (61.069.03)

- DNV

- ABS (American Bureau of Shipping)

These certifications assure you of the quality, reliability, and compliance of the Aluminum Welding Wire ER5356, providing peace of mind for every welding project.

Why Choose Kunli's Aluminum Welding Wire ER5356?

- Superior Corrosion Resistance: Ideal for marine, aerospace, and automotive applications.

- High Strength: Excellent tensile and yield strength for reliable welds in high-stress environments.

- Versatility: Suitable for both TIG and MIG welding processes, making it perfect for a wide range of applications.

- Certifications: Kunli's ER5356 aluminum welding wire meets the highest industry standards, ensuring durability and reliability.

Choose Kunli for your aluminum welding wire needs and experience unmatched quality and performance. Contact us today for more information or to place an order.

Aluminum Welding Wire ER5356

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Your Complete Guide to Aluminum Braided Wire Explained

Jan 30, 2026

When electrical connections need to flex, resist vibration, or distribute current across irregular surfaces, engineers i...

-

How Wire Cast and Helix Influence MIG Weld Feed Stabili...

Jan 23, 2026

Welding professionals working with aluminum face unique challenges that their steel welding counterparts rarely encounte...

-

Why is ER5183 Welding Wire the Industry Standard for Ma...

Jan 26, 2026

In the demanding fields of naval architecture and liquefied natural gas (LNG) infrastructure, material failure is not an...

-

How Wire Cast and Helix Affect MIG Welding Performance

Jan 19, 2026

Welding professionals working with aluminum face unique challenges that their steel welding counterparts rarely encounte...

Industry Information Extension

More Information About Aluminum Welding Wire ER5356

Optimizing MIG & TIG Welding Performance with Aluminum Welding Wire ER5356

When working with aluminum alloys, selecting the right ER5356 aluminum welding wire can significantly impact weld quality, strength, and corrosion resistance. This versatile filler metal is particularly well-suited for MIG and TIG welding applications, especially when joining 5XXX series aluminum alloys commonly used in marine, automotive, and structural fabrication.

Why Choose Aluminum Welding Wire ER5356?

ER5356 stands out among aluminum welding wires due to its 5% magnesium content, which provides:

- Higher tensile strength (~290 MPa) compared to ER4043

- Better crack resistance in high-stress applications

- Superior corrosion resistance in saltwater environments

- Excellent ductility for structural and dynamic load applications

For welders working on boat hull repairs or aluminum trailer fabrication, ER5356 offers distinct advantages over other filler wires. Its compatibility with marine-grade aluminum alloys like 5052, 5083, and 5454 makes it a top choice for offshore welding projects.

MIG Welding Techniques with ER5356

When setting up for MIG welding aluminum with ER5356, proper equipment configuration is crucial:

Recommended Parameters:

- Wire diameter: 0.8mm-1.2mm (0.030"-0.045")

- Shielding gas: 75% argon/25% helium mix (improves penetration)

- Voltage range: 18-22V (for 1.0mm wire)

- Wire feed speed: 5-8 m/min

To prevent common aluminum MIG welding problems like porosity or poor fusion:

- Use a push technique (torch angle 10-15°)

- Maintain proper contact tip to work distance (10-15mm)

- Ensure aluminum-specific drive rolls to prevent wire deformation

TIG Welding Applications

For precision work on aluminum pipe welding or thin gauge aluminum fabrication, TIG welding with ER5356 produces clean, high-quality welds:

Optimal TIG Settings:

- Tungsten electrode: 2% ceriated or zirconiated

- AC balance: 70% EN (cleaning action)

- Preheat: 150-250°F for thick sections (>6mm)

- Filler rod diameter: Match to base metal thickness

The anodizing compatibility of ER5356 makes it preferable for visible welds where a uniform finish is required, though it may show a slight gray tint compared to ER4043's darker appearance.

ER5356 vs. ER4043: Selecting the Right Filler

| Parameter | ER5356 | ER4043 |

|---|---|---|

| Tensile Strength | 290 MPa | 186 MPa |

| Elongation | 10-15% | 12-18% |

| Color After Anodizing | Light Gray | Dark Gray |

| Magnesium Content | 5% | 0% |

| Best Applications | Marine, Structural | Castings, Decorative |

| Corrosion Resistance | Excellent (saltwater) | Good |

| Weld Cracking Resistance | High | Moderate |

FAQ about Aluminum Welding Wire ER5356

Can ER5356 be used for welding 6061 aluminum?

- Yes, but post-weld heat treatment may be needed for maximum strength in 6061 applications.

What's the best shielding gas for ER5356 MIG welding?

- A 75% Ar/25% He mix provides optimal penetration for thicker aluminum sections.

How does ER5356 compare to other aluminum welding wires?

- ER5356 offers superior corrosion resistance and strength, particularly for applications exposed to saltwater, such as in the marine and automotive industries.

Can ER5356 be used for TIG welding?

- Yes, ER5356 is highly recommended for TIG welding, providing smooth arc stability and excellent weld appearance.

What are the key benefits of using ER5356 aluminum welding wire?

- ER5356 offers superior corrosion resistance, high strength, easy weldability, and excellent fatigue strength.

Can ER5356 be used for welding high-stress components?

- Yes, ER5356 is ideal for high-stress welding applications, thanks to its high tensile strength and fatigue resistance.

Is ER5356 suitable for welding thin materials?

- Yes, ER5356 is suitable for welding thin materials, offering precise welds with minimal heat input.

Can ER5356 be used for MIG welding?

- Yes, ER5356 can also be used for MIG welding, providing excellent weld bead appearance and arc stability.

How does ER5356 perform in high-temperature environments?

- ER5356 is heat-resistant, making it suitable for applications exposed to elevated temperatures, such as in automotive exhaust systems and pressure vessels.

What is the recommended storage condition for ER5356 welding wire?

- Store ER5356 welding wire in a dry, cool place, away from moisture and contaminants to prevent corrosion.

What are the advantages of ER5356 over ER4045?

- ER5356 offers better corrosion resistance and fatigue strength compared to ER4045, making it ideal for marine and high-stress applications.