Aluminum Welding Wire

ER2319 Aluminum Welding Wire

2319 is about 6% Copper Aluminum filler metal which has high strength, excellent seawater corrosion resistance, better bending property and high fracture toughness, recommended for welding the construction of parts of 2xxx series; mainly apply to the air and spacecraft industries.

ER2319 is an aluminum-copper alloy welding wire designed for welding 2219 aluminum alloy. It has good welding performance and high strength, and is widely used in aerospace, shipbuilding and chemical equipment.

Product Features:

Excellent welding performance: ER2319 welding wire has good fluidity, beautiful weld formation and easy operation.

High strength: The strength of the joint after welding is high, which can reach more than 90% of the strength of the parent material.

Good corrosion resistance: The weld has good corrosion resistance and is suitable for harsh environments.

Low crack sensitivity: The crack tendency during welding is low, and the welding quality is stable and reliable.

Product parameters:

Material: AlCu6Mn

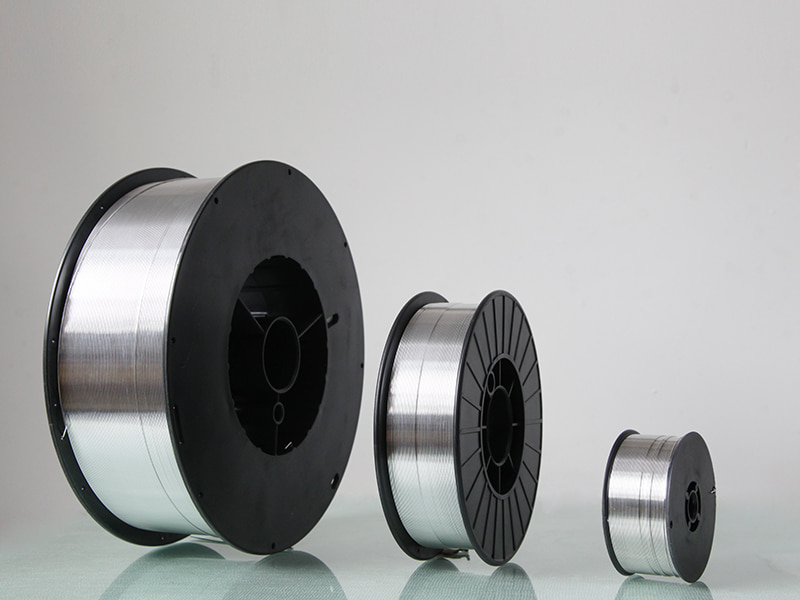

Diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.2mm (customizable according to customer needs)

Standard: AWS A5.10 ER2319, GB/T 10858 ER2319

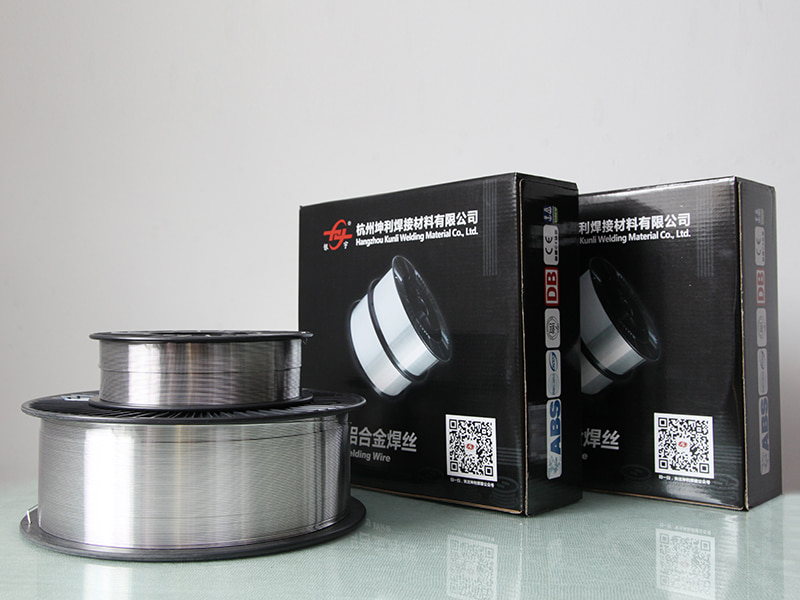

Packaging: 10kg/dish, 15kg/dish

Application scenarios:

Aerospace: used for welding key components such as aircraft fuselage and rocket fuel tanks.

Shipbuilding: used for welding hull structures, decks, cabins, etc.

Chemical equipment: used for welding pressure vessels, heat exchangers, pipelines, etc.

Other fields: can also be used for welding bicycle frames, auto parts, etc.

ER2319 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

What is the Maximum Service Temperature for Components ...

Feb 11, 2026

In the field of cryogenic and structural aluminum fabrication, alloy er4043 (Al-Si5) is the most widely utilized filler ...

-

Does Using ER5183 Welding Wire Significantly Improve th...

Feb 09, 2026

In the field of high-performance metallurgy, selecting the appropriate filler metal is paramount for ensuring the struct...

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

-

General-Purpose vs Structural Aluminum Welding Wire Gui...

Feb 04, 2026

Selecting the right aluminum welding wire starts with grasping how its alloy makeup affects everything from how it flows...

Industry Information Extension

More Information About ER2319 Aluminum Welding Wire Suppliers

Why ER2319 is the Top Choice for Aluminum Tank and Pressure Vessel Welding?

When it comes to welding aluminum tanks and pressure vessels, selecting the right filler wire is crucial for ensuring structural integrity, corrosion resistance, and long-term performance. ER2319 aluminum welding wire has emerged as a top choice in industries requiring high-strength, crack-resistant welds, particularly in aerospace-grade aluminum alloys and cryogenic storage applications.

Key Advantages of ER2319 for Tanks & Pressure Vessels

1. Superior Strength & Crack Resistance

ER2319 is specifically designed for welding 2219 aluminum alloy, which is widely used in high-pressure tanks, LNG storage, and rocket fuel containers. Unlike ER4043 or ER5356, which are softer, ER2319 filler wire provides higher tensile strength (up to 310 MPa) and better resistance to hot cracking—a common issue in thick aluminum welds.

2. Excellent Performance in Cryogenic Conditions

For low-temperature applications (e.g., liquid nitrogen tanks, space launch systems), ER2319 maintains superior ductility and toughness, even at -250°C (-418°F). This makes it ideal for cryogenic pressure vessels where thermal stress resistance is critical.

3. Optimized for TIG & MIG Welding Processes

Whether using TIG (GTAW) or MIG (GMAW) welding, ER2319 delivers consistent arc stability and low porosity. Its copper (Cu) content (5.8-6.8%) enhances weld fluidity, reducing the risk of lack of fusion defects—especially in thick aluminum plate welding (10mm+).

4. Corrosion Resistance in Harsh Environments

While ER5356 filler wire is more common for marine applications, ER2319 offers better stress corrosion cracking (SCC) resistance in chemical storage tanks and high-pressure gas cylinders. Post-weld heat treatment (PWHT) can further enhance its corrosion performance.

ER2319 vs. Other Aluminum Filler Wires: Key Parameters

| Parameter | ER2319 | ER4043 | ER5356 |

|---|---|---|---|

| Base Alloy | 2219 Aluminum | 6061, 3003 | 5052, 5083 |

| Tensile Strength | 310 MPa | 186 MPa | 290 MPa |

| Cu Content | 5.8-6.8% | ≤0.3% | ≤0.1% |

| Best For | High-strength tanks | General-purpose | Marine applications |

| Cryogenic Use | Excellent | Poor | Moderate |