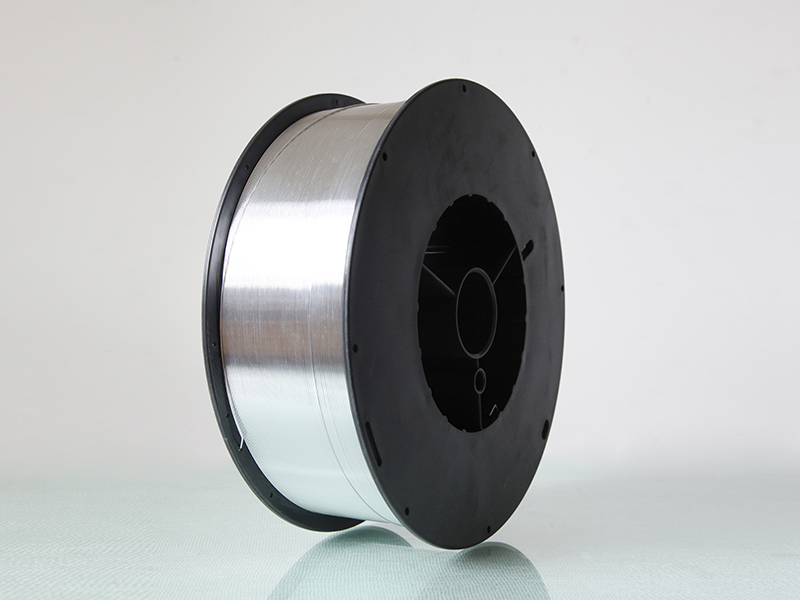

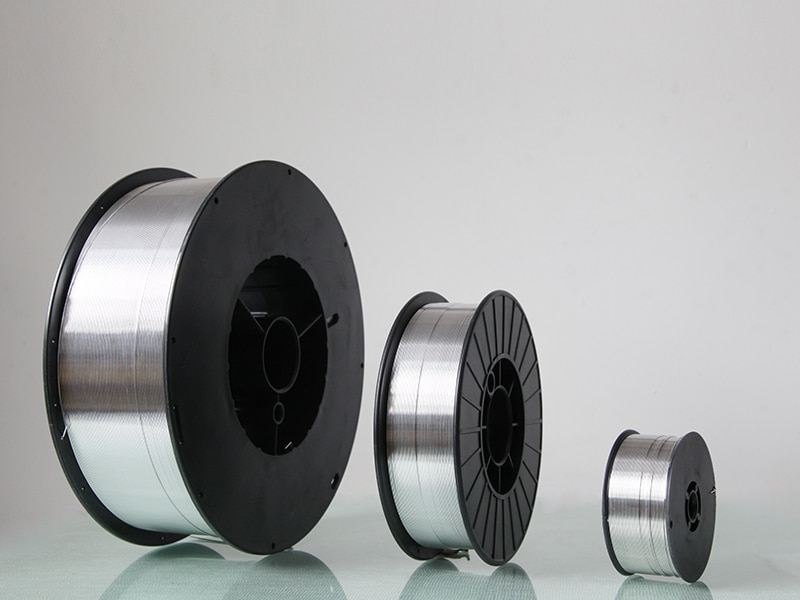

Aluminum Welding Wire

ALUMINUM ALLOY WIRE FOR 3D PRINTING

Aluminum alloy wire for 3DP is for arc additive manufacturing (wire+arc additive manufacturing, WAAM). Comparing with Laser solid forming, WAAM can save the process of producing Al powder, avoid oxidation and the problem of lower deposition rate because of the higher flectivity while Laser is working on the surface of Al material. The Aluminum alloy wire for 3D printing is 2000 series, 5000 series, and 6000series, like suitable for the complicated construction in the area of air and spacecraft, energy, auto mobile etc.

Currently, we can produce 2195,2319, 114A and 205A.

Aluminum Alloy Wire For 3D Printing Product Features

Lightweight and high strength: Aluminum alloy materials have the characteristics of high strength and light weight, and are suitable for application scenarios that need to reduce weight but maintain strength.

Corrosion resistance: Aluminum alloys have good corrosion resistance and are suitable for the manufacture of parts in harsh environments.

High thermal conductivity: Aluminum alloys have high thermal conductivity and are suitable for parts that need to dissipate heat.

Post-processability: Aluminum alloy materials are easy to machine and weld, and are suitable for complex post-processing processes.

Wide range of applications: Aluminum alloys are suitable for a variety of 3D printing technologies, such as selective laser melting (SLM), directed energy deposition (DED) and binder jetting.

Product parameters

Main alloy components: Common aluminum alloys include AlSi10Mg, AlSi12, AlSi7Mg, etc. These alloys have different mechanical properties and chemical compositions.

Mechanical properties:

AlSi10Mg: has good comprehensive properties and is suitable for the manufacture of high-strength and high-toughness parts.

AlSi12: lightweight and has excellent thermal properties, suitable for the manufacture of thin-walled parts and complex geometries.

AlSi7Mg: Combines the strengthening effects of silicon and magnesium, suitable for applications with high strength requirements.

Printing parameters:

Printing speed: Adjusted according to the specific equipment and material characteristics, usually between 500-1000 mm/min.

Layer thickness: 0.1-0.5 mm, depending on the printing accuracy requirements.

Temperature range: The printing temperature needs to be adjusted according to the alloy type, usually between 600-800°C.

Application scenarios

Aerospace: Aluminum alloys are widely used in the manufacture of aircraft structural parts, engine components and spacecraft components due to their light weight and high strength.

Automotive industry: Used to manufacture automotive parts such as engine brackets, suspension systems and body structural parts to reduce weight and improve fuel efficiency.

Industrial machinery: Suitable for manufacturing parts of industrial machinery, such as gears, bearing seats and brackets, and are favored for their wear resistance and high strength.

Consumer electronics: Used to manufacture mobile phone cases, laptop cases, etc., and are popular for their light weight, high strength and aesthetics.

Medical devices: Suitable for manufacturing medical devices and implants due to its biocompatibility and good mechanical properties.

ALUMINUM ALLOY WIRE FOR 3D PRINTING

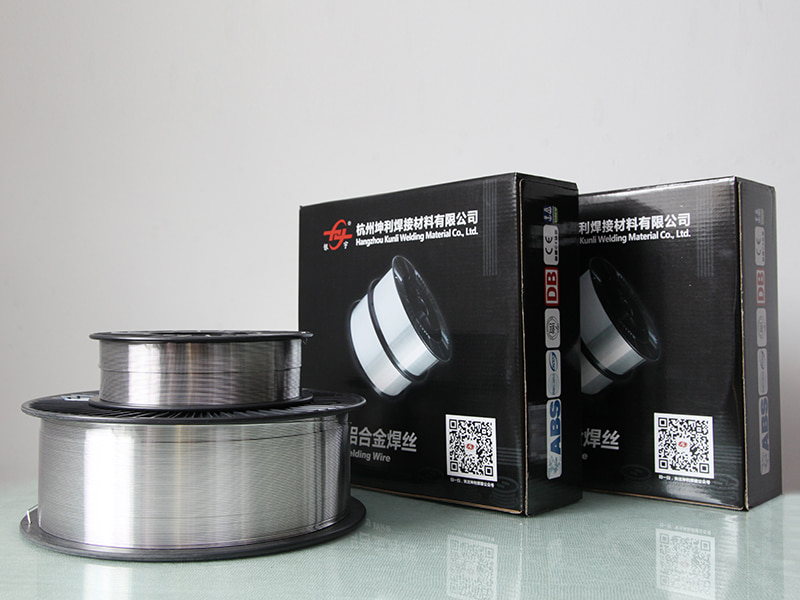

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Why is ER4047 Welding Wire the Preferred Choice for Lea...

Feb 06, 2026

In the high-precision manufacturing of automotive heat exchangers—such as radiators, condensers, and evaporators—the int...

-

General-Purpose vs Structural Aluminum Welding Wire Gui...

Feb 04, 2026

Selecting the right aluminum welding wire starts with grasping how its alloy makeup affects everything from how it flows...

-

Aluminum Welding Wire ER5356: Marine & Auto — Why It Wo...

Feb 02, 2026

Repair facilities that fix damaged boats, offshore gear, or automotive frames have to think past the quick patch job. Th...

-

Your Complete Guide to Aluminum Braided Wire Explained

Jan 30, 2026

When electrical connections need to flex, resist vibration, or distribute current across irregular surfaces, engineers i...

Industry Information Extension

More Information About ALUMINUM ALLOY WIRE FOR 3D PRINTING Suppliers

Real-Time Monitoring Systems for Aluminum Wire 3D Printing: Reducing Defects in Metal AM Processes

The growing adoption of aluminum alloy wire for 3D printing in industries like aerospace, automotive, and energy has driven demand for higher precision and defect-free manufacturing. One of the most promising advancements in this field is the integration of real-time monitoring systems for wire arc additive manufacturing (WAAM), ensuring consistent quality in aluminum wire-fed 3D printing processes.

Why Real-Time Monitoring Matters in Aluminum Wire 3D Printing?

Unlike traditional powder-based metal 3D printing, aluminum wire 3D printing relies on continuous wire deposition, making it prone to defects like porosity, lack of fusion, and inconsistent bead geometry. Real-time monitoring systems address these challenges by:

Tracking arc stability in aluminum WAAM processes to prevent spatter and uneven deposition.

Monitoring melt pool dynamics to optimize heat input and reduce cracking in high-strength aluminum alloys like ER4043 and ER5356.

Detecting geometric deviations using laser scanners or vision-based systems, ensuring dimensional accuracy in large-scale aluminum wire AM.

Key Technologies in Real-Time Monitoring for Aluminum Wire AM

Optical Emission Spectroscopy (OES) – Measures plasma emissions during welding to detect impurities in aluminum alloy wire for additive manufacturing.

Infrared Thermography – Tracks temperature distribution to prevent overheating in thin-wall aluminum wire 3D printing.

High-Speed Cameras + AI Analysis – Identifies defects like porosity in real-time, crucial for aerospace-grade aluminum wire deposition.

Performance Comparison: ER4043 vs. ER5356 in Monitored WAAM

| Parameter | ER4043 (Al-Si Alloy) | ER5356 (Al-Mg Alloy) |

|---|---|---|

| Crack Resistance | High (Good for high-heat apps) | Moderate (Prone to hot cracking) |

| Wire Feed Speed | 6-8 m/min (Optimal) | 5-7 m/min (Stable) |

| Porosity Risk | Low (Si reduces voids) | Moderate (Mg increases gas absorption) |

| Post-Processing Ease | Excellent (Smooth finish) | Good (May require more machining) |

| Typical Applications | Heat exchangers, automotive parts | Marine components, structural welds |