Introduction

Wire Arc Additive Manufacturing (WAAM) is a cost-effective method for producing large-scale aluminum parts. This process requires filler wire that meets stricter standards than traditional welding. Our WAAM-grade aluminum wire is manufactured with ultra-tight chemical tolerances and superior surface cleanliness to minimize porosity and inclusion defects in the final printed part. The precision layer winding and consistent diameter ensure uninterrupted feeding, which is paramount for the long, continuous deposition runs characteristic of 3D printing.

Specification

| Process Focus | Wire Arc Additive Manufacturing (WAAM), GMAW-AM |

| Key Property | Ultra-low porosity, High print resolution, Batch consistency |

| Material Focus | ER2319, ER4043, ER5183, and specialized Al-Si/Al-Mg alloys |

| Supply Form | Large drums or continuous spools for long print cycles |

| Tolerance | Extremely tight diameter and chemistry control |

Applications

Large-scale prototyping and final part production in aerospace and defense.

Additive manufacturing of customized tooling, molds, and repair parts.

On-demand manufacturing of specialized marine and oil & gas components.

R&D and commercial deployment of Metal 3D Printing systems.

Payment and Shipping

R&D Support: Collaboration with WAAM system manufacturers and research institutions for material optimization.

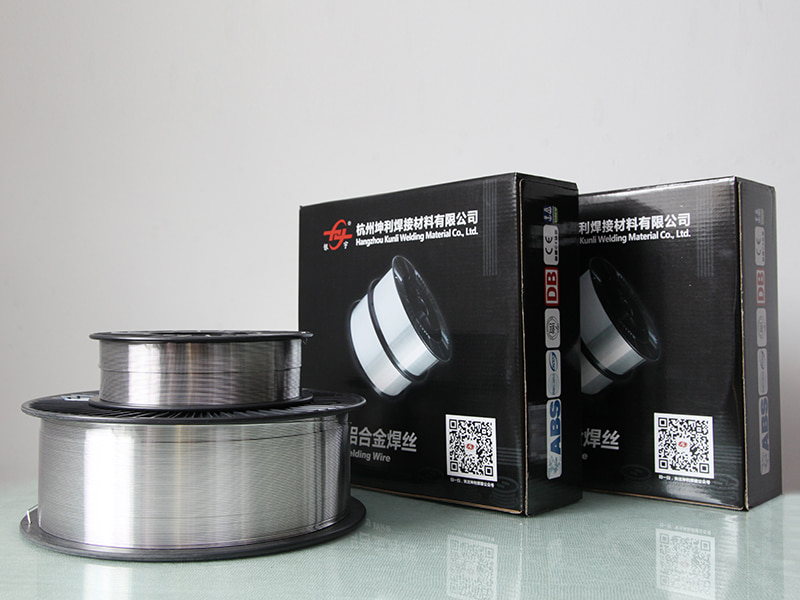

Packaging: Specialized protective packaging to ensure material cleanliness is preserved until it enters the AM system.

Traceability: Full documentation of chemical analysis for every batch to support part validation.

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch