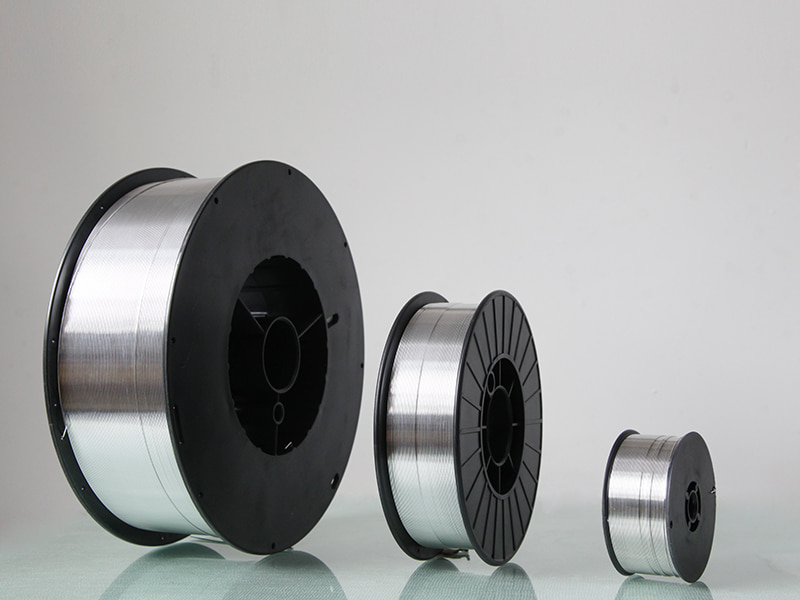

ER5087 Magnesium Aluminum Welding Wire: High-Strength Solution for Marine & Industrial Use

ER5087 Aluminum Welding Wire for Marine Applications – Corrosion-Resistant & Durable

The ER5087 magnesium aluminum welding wire is a top choice for marine welding due to its excellent corrosion resistance and high strength. Designed for welding 5XXX series aluminum alloys, it is widely used in shipbuilding, offshore platforms, and other saltwater-exposed structures. The wire’s magnesium content enhances weld durability, making it ideal for harsh marine environments where resistance to seawater corrosion is critical.

ER5087 Aluminum Welding Wire Datasheet – Key Properties & Performance

A detailed ER5087 aluminum welding wire datasheet reveals its superior mechanical properties, including high tensile strength (up to 290 MPa) and excellent crack resistance. This filler wire is compatible with MIG and TIG welding processes, ensuring smooth arc stability and minimal spatter. Its low melting point and good fluidity make it suitable for thin and thick aluminum sheets alike.

ER5087 Aluminum Welding Wire Specifications – Composition & Applications

The ER5087 aluminum welding wire specifications highlight its Al-Mg alloy composition, typically containing 4-5% magnesium for enhanced strength and ductility. It meets AWS A5.10 standards and is widely used in:

Marine construction (hulls, decks, pipelines)

Automotive & aerospace (lightweight structural welding)

Pressure vessels & storage tanks (high-integrity joints)

Why Choose ER5087 Welding Wire?

Superior corrosion resistance (ideal for saltwater applications)

High weld strength & fatigue resistance

Excellent weldability with minimal porosity

For industries requiring durable, high-performance aluminum welds, ER5087 magnesium aluminum welding wire remains a trusted solution. Whether for marine or industrial use, its reliability and strength make it a preferred choice among welders worldwide.

NEXT:Aluminum Welding Wire ER5087: Decoding numbers and codes

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire