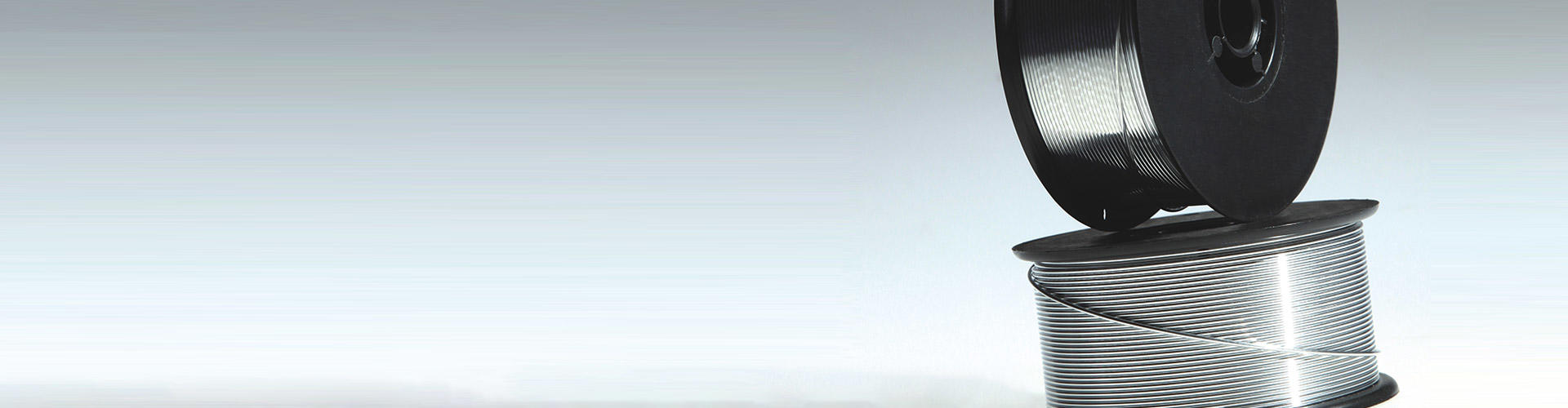

Aluminum Welding Wire

ER5754 Aluminum Welding Wire

5754 is about 3% Magnesium Aluminum filler metal which has medium strength, better seawater corrosion resistance, recommended for welding the construction of parts of 5000 series, 6000 series, such as 5083, 6061,6063, 5086 etc.;

Product description

ER5754 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

How does Aluminum Welding Wire ensure that welded alumi...

May 16, 2024

In the construction industry, Aluminum Welding Wire is often used for welding aluminum doors, windows and curtain walls....

-

How does Aluminum Welding Wire avoid the impact of the ...

May 09, 2024

In the aerospace field, for aluminum parts that have strict requirements for lightweight and high thermal conductivity, ...

-

Gas-metal-arc welding (GMAW) is a common method of weld...

May 02, 2024

How to Weld Aluminum Welding WireAluminum Welding WireGas-metal-arc welding (GMAW) is a common method of welding aluminu...

-

How to ensure high strength of the weld when using Alum...

Apr 25, 2024

In the chemical industry, many equipment and pipelines need to handle corrosive media. When using Aluminum Welding Wire ...

Industry Information Extension

More Information About ER5754 Aluminum Welding Wire

What are the advantages of ER5754 aluminum welding wire in automobile manufacturing

High Strength: ER5754 welding wire has a high strength-to-weight ratio, making it ideal for use in automotive manufacturing. It offers superior strength compared to other welding alloys, which makes it a reliable choice for critical components that require maximum strength and durability.

Corrosion Resistance: ER5754 welding wire is highly resistant to corrosion and has excellent resistance to environmental factors such as salt water and harsh weather conditions. This makes it ideal for automotive applications where the vehicle is exposed to harsh environments.

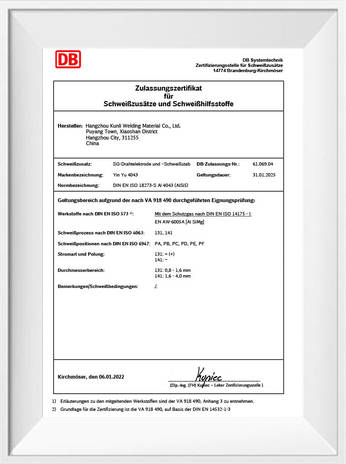

Weldability: ER5754 welding wire has excellent weldability and can be easily welded using a variety of welding techniques, including MIG, TIG, and gas welding. This makes it a popular choice for automotive manufacturing, where a high degree of precision and accuracy is required.

Cost-effective: ER5754 welding wire is relatively inexpensive compared to other welding alloys, making it a cost-effective choice for automotive manufacturers who are looking for a high-quality welding wire that is also affordable.

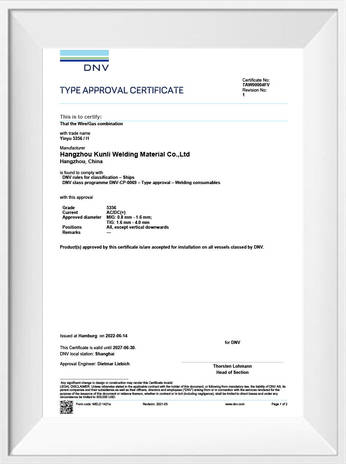

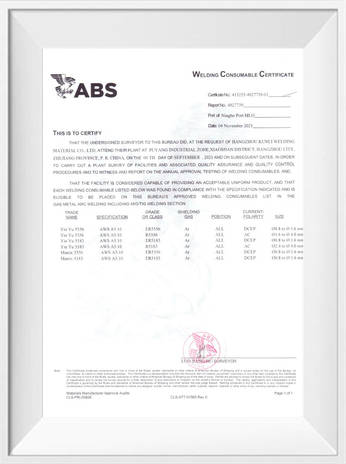

What are the key considerations when selecting ER5754 aluminum welding wire for marine applications

Corrosion Resistance: Marine environments are highly corrosive, and therefore, the corrosion resistance of the welding wire is a critical factor to consider. ER5754 welding wire has excellent corrosion resistance, making it a suitable choice for marine applications. However, it is essential to ensure that the welding wire is used in conjunction with appropriate welding techniques and protective coatings to prevent corrosion and prolong the lifespan of the component.

Strength: In marine applications, the welding wire must have sufficient strength to withstand the harsh marine environment. ER5754 welding wire has high strength, making it suitable for marine applications where the component must withstand high stresses and loads. However, it is essential to ensure that the welding wire is compatible with the base material to achieve optimal strength.

Weldability: Weldability is a crucial factor to consider when selecting welding wire for marine applications. ER5754 welding wire has good weldability and can be easily welded using a variety of welding techniques, including MIG, TIG, and gas welding. However, it is essential to ensure that the welding wire is compatible with the base material to achieve a strong and durable weld.

Cost-effectiveness: Cost is an important consideration when selecting welding wire for marine applications. ER5754 welding wire is relatively inexpensive compared to other welding alloys, making it a cost-effective choice for marine manufacturers who are looking for a high-quality welding wire that is also affordable.

Compatibility with Protective Coatings: In marine applications, the component must be protected from the corrosive marine environment by applying protective coatings. Therefore, it is essential to ensure that the welding wire is compatible with the protective coating to prevent the coating from delaminating and compromising the protection of the component.

Regulatory Compliance: Marine components are subject to stringent regulations and standards, and it is essential to ensure that the welding wire is compliant with these regulations. ER5754 welding wire is compliant with many marine standards, including ASTM B209 and AWS A5.10, making it a suitable choice for marine applications.

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch