Aluminum Alloy Wire

5154 Aluminum Alloy Welding Wire

Grade 5154, Al-Mg alloy wire is used for braiding in coaxial cable for shielding, with it's good performance.

Main Application: flexible coaxial cable, a variety of audio and video cable, vehicle signal cable, network cable, data transmission cable and so on.

Product description

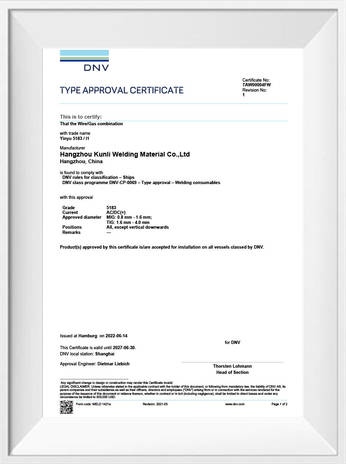

5154 aluminum alloy welding wire is a welding material commonly used for aluminum and aluminum alloy welding. It has corrosion resistance and strength and is suitable for welding in marine environments and high-strength structures. Its main application areas include shipbuilding, chemical equipment, construction engineering and aerospace.

Product Features

Alloy composition:

Main components: High magnesium (Mg) content, usually between 3.0%-5.0%. The core components of 5154 aluminum alloy welding wire are aluminum, magnesium and a small amount of silicon, iron, copper and other elements. The proportion of these elements determines its strength, toughness and corrosion resistance.

Alloying characteristics: The high magnesium content makes the welded metal have good corrosion resistance, especially in seawater environment.

Mechanical properties:

High strength, good tensile strength and yield strength.

The strength of the welded joint is close to that of the parent material, which can meet the needs of high-load environments.

It has good fatigue resistance after welding, especially for structures requiring high strength.

Welding performance:

Good weldability, suitable for conventional welding processes such as MIG (gas shielded metal arc welding) and TIG (tungsten inert gas arc welding). There is less spatter during welding, the welding process is smooth and easy to operate.

The surface of the welded joint is smooth and the weld is well formed.

Corrosion resistance:

It has excellent resistance to salt water and atmospheric corrosion, and is particularly suitable for welding operations in marine environments.

It can also show good corrosion resistance in acidic and alkaline environments.

Chemical composition (in wt%):

Aluminum (Al): balance

Magnesium (Mg): 3.0-5.0%

Silicon (Si): ≤0.30%

Copper (Cu): ≤0.10%

Iron (Fe): ≤0.40%

Manganese (Mn): ≤0.20%

Titanium (Ti): ≤0.15%

Mechanical properties (under standard conditions):

Tensile strength: 250-310 MPa

Yield strength: ≥ 180 MPa

Elongation: ≥ 10-12%

Hardness: 60-75 HB (Brinell hardness)

Welding process parameters:

Welding current: DC power supply, welding current range is usually 120-220 A (depending on welding process and material thickness).

Shielding gas: pure argon or a mixture of argon and a small amount of helium.

Welding position: suitable for various welding positions such as flat welding, vertical welding and horizontal welding.

Heat-affected zone:

Due to its good thermal conductivity, the heat-affected zone generated by 5154 welding wire during welding is small, which can effectively reduce the generation of thermal cracks.

Scope of application/scenario

Shipbuilding and maintenance:

Since the surface of aluminum alloy in the marine environment is prone to corrosion, 5154 aluminum alloy welding wire is very suitable for welding hulls and ship equipment.

It is mainly used in high-strength and corrosion-resistant structural parts such as hull structures, ship external frames, and platforms.

Marine engineering:

In offshore oil and gas platforms, wind power platforms and other projects, 5154 aluminum alloy welding wire is widely used for welding steel structures and aluminum alloy parts to ensure corrosion resistance and structural strength.

Automobiles and vehicles:

5154 aluminum alloy welding wire is often used for welding aluminum alloy parts such as automobiles, trucks, and rail transportation, such as car bodies, aluminum alloy frames, engine parts, etc., which can improve welding strength and enhance corrosion resistance.

Aerospace:

In aircraft and spacecraft manufacturing, 5154 welding wire is used to weld aluminum alloy parts such as wings, fuselages and other key structural parts to ensure structural safety and durability.

Chemical Equipment:

In chemical equipment, especially equipment involving the transportation and storage of acids, alkalis and corrosive liquids, the corrosion resistance of 5154 aluminum alloy welding wire makes it an ideal choice.

5154 Aluminum Alloy Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

Aluminum Welding Wire Selection Guide: Matching Alloy t...

Jul 03, 2025

Navigating the complexities of aluminum welding demands not just skill but the partner in materials. Aluminum Alloy Weld...

-

Why Engineers Trust Aluminum Braided Wire Manufacturers...

Jun 30, 2025

Electrical and mechanical engineers constantly seek materials that balance conductivity, durability, and adaptability. I...

-

Unlock Your TIG Potential: Kunliwelding's Precision Wir...

Jun 25, 2025

The relentless drive for efficiency and performance across industries-from the soaring ambitions of aerospace to the sle...

-

ER5356 Aluminum Welding Wire: The Complete Guide to Tec...

Jul 04, 2025

Comprehensive Overview of ER5356 Aluminum Welding Wire Properties and Characteristics When it comes to welding aluminum ...

Industry Information Extension

More Information About 5154 Aluminum Alloy Welding Wire

Key points for storage and pretreatment of 5154 aluminum alloy welding wire: key steps to avoid pores and oxidation

I. Storage environment control

Humidity requirements:

The relative humidity of the storage environment needs to be controlled at ≤40% (it is recommended to use a constant temperature and humidity cabinet). Aluminum welding wire is prone to weld pores (H₂ pores) after absorbing moisture.

Welding wire that has not been used up after unpacking needs to be sealed with a moisture-proof bag and placed with a desiccant.

Temperature and expiration:

The storage temperature is recommended to be 10-25℃ to avoid high temperature accelerated oxidation.

The shelf life of unopened welding wire is usually 1-2 years (please refer to the manufacturer's instructions). It is recommended to use it up within 72 hours after opening.

II. Welding wire pretreatment measures

Surface cleaning:

Use acetone or special aluminum cleaning agent to remove oil stains and oxide film (Al₂O₃) on the surface of the welding wire. The oxide film has a high melting point (2050℃) and is prone to cause unfused defects.

It is forbidden to touch it with bare hands after cleaning to avoid secondary contamination.

Drying treatment:

If the welding wire is exposed to a humid environment for more than 4 hours, it needs to be dried at 120-150℃ for 1-2 hours (do not overheat to avoid burning of magnesium).

III. Key inspections before welding

Confirmation of welding wire status:

Observe whether the surface is black (severe oxidation needs to be scrapped) and whether there are burrs (may cause poor wire feeding).

Shielding gas detection:

Use high-purity argon (≥99.99%), and the oxygen content must be <0.001% to prevent weld oxidation.

IV. Common problems and countermeasures in the industry

Problem 1: Dense pores in the weld

Reason: The welding wire is damp or the shielding gas is impure.

Solution: Dry the welding wire + detect gas pipeline leakage.

Problem 2: Unstable wire feeding

Reason: The welding wire is bent or the surface oxide layer is too thick.

Solution: Replace the wire reel and adjust the wire feeding wheel pressure.

V. Extended suggestions

For high-demand scenarios (such as aerospace and ships), it is recommended to purchase vacuum-packed welding wire and equip it with a constant temperature storage cabinet for welding wire.

Regularly calibrate welding equipment parameters to ensure that the wire feeding speed matches the current (recommended wire feeding speed for 5154 welding wire: 5-8m/min).

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch