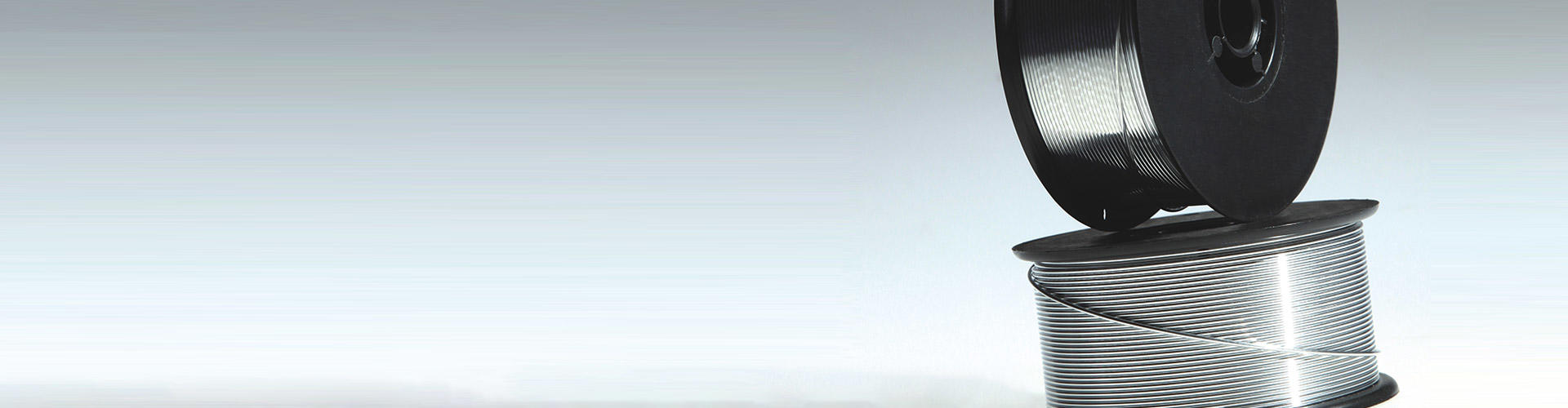

Aluminum Welding Wire

ER4047 Aluminum Mig Welding Wire

Product description

ER4047 Aluminum Mig Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

How does Aluminum Welding Wire ensure that welded alumi...

May 16, 2024

In the construction industry, Aluminum Welding Wire is often used for welding aluminum doors, windows and curtain walls....

-

How does Aluminum Welding Wire avoid the impact of the ...

May 09, 2024

In the aerospace field, for aluminum parts that have strict requirements for lightweight and high thermal conductivity, ...

-

Gas-metal-arc welding (GMAW) is a common method of weld...

May 02, 2024

How to Weld Aluminum Welding WireAluminum Welding WireGas-metal-arc welding (GMAW) is a common method of welding aluminu...

-

How to ensure high strength of the weld when using Alum...

Apr 25, 2024

In the chemical industry, many equipment and pipelines need to handle corrosive media. When using Aluminum Welding Wire ...

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch