Aluminum Welding Wire

ER5356 Aluminum Welding Wire

Mainly apply to furniture, sports equipment, compressed container, ships, rail transportation and the automotive industry and so on.

Product description

ER5356 Aluminum Welding Wire

Coming From China,

Marketing To The World.

-

30+

USED IN HEAVY INDUSTRY TECHNOLOGY SECTOR

-

35

YEARS OF RESEARCH AND DEVELOPMENT EXPERIENCE

-

200+

COOPERATIVE LARGE-SCALE R & D INSTITUTIONS

-

20+

GLOBAL TRADE COUNTRIES AND REGIONS

Coming From China,

Marketing To The World.

More than 90% of our field operators have professional and technical education background, and have many years of experience in equipment processing and assembly. It is precisely because of this united, dedicated, pioneering, skilled and experienced team that the company's technology and products can be continuously updated and improved.

Send Us a Message?

Related Products

-

View More

View More

Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

::: Last News :::

-

How does Aluminum Welding Wire ensure that welded alumi...

May 16, 2024

In the construction industry, Aluminum Welding Wire is often used for welding aluminum doors, windows and curtain walls....

-

How does Aluminum Welding Wire avoid the impact of the ...

May 09, 2024

In the aerospace field, for aluminum parts that have strict requirements for lightweight and high thermal conductivity, ...

-

Gas-metal-arc welding (GMAW) is a common method of weld...

May 02, 2024

How to Weld Aluminum Welding WireAluminum Welding WireGas-metal-arc welding (GMAW) is a common method of welding aluminu...

-

How to ensure high strength of the weld when using Alum...

Apr 25, 2024

In the chemical industry, many equipment and pipelines need to handle corrosive media. When using Aluminum Welding Wire ...

Industry Information Extension

More Information About ER5356 Aluminum Welding Wire

What is ER5356 aluminum welding wire, and what are its applications in the welding industry

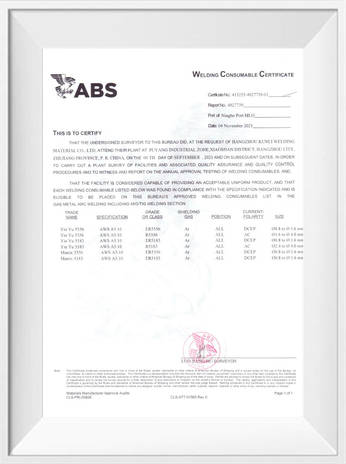

Marine Components: ER5356 aluminum welding wire is commonly used to weld marine components such as boat hulls, masts, and deck fittings. The wire's high strength and corrosion resistance make it ideal for marine applications where the welded joint must withstand exposure to saltwater and other harsh environments.

Bicycles: ER5356 aluminum welding wire is also used to weld bicycle frames and components. The wire's high strength-to-weight ratio and corrosion resistance make it an excellent choice for lightweight bicycle frames that can withstand the rigors of cycling.

Automotive Parts: ER5356 aluminum welding wire is used in the automotive industry to weld components such as engine blocks, cylinder heads, and transmission cases. The wire's high strength and corrosion resistance make it an ideal choice for parts that are exposed to heat, moisture, and other harsh conditions.

Benefits: ER5356 aluminum welding wire offers several benefits in addition to its strength and corrosion resistance. It has a low melting point, which means that it requires less heat to weld than other types of welding wire. This results in less distortion and reduces the risk of burn-through. The wire also produces a clean weld with minimal spatter, which reduces the need for post-weld cleaning and saves time and money.

Welding Technique: Welding with ER5356 aluminum welding wire requires a specific welding technique. It is important to use the correct angle and travel speed to ensure a strong, clean weld. Welders must also use a welding machine with a high amperage output and a specialized welding technique that allows for precise control of the weld temperature.

How does using ER5356 Aluminum Welding Wire impact the quality and durability of aluminum welds

ER5356 Aluminum Welding Wire is a popular choice for welding aluminum due to its high tensile strength and corrosion resistance. When used correctly, this welding wire can produce strong and durable welds that meet or exceed industry standards. However, there are several factors to consider when using ER5356 welding wire that can impact the quality and durability of aluminum welds.

One of the most important factors to consider is the type of aluminum being welded. ER5356 welding wire is designed specifically for welding aluminum alloys that have a magnesium content of 5% or higher. If the aluminum being welded has a lower magnesium content, a different welding wire may be needed to achieve the desired results.

Another important factor to consider is the welding technique being used. ER5356 welding wire is typically used with the gas metal arc welding (GMAW) process, also known as MIG welding. However, the welding parameters such as current, voltage, and wire feed speed, need to be properly set to avoid issues such as porosity, cracking, or lack of penetration.

It is also important to ensure that the aluminum being welded is clean and free of contaminants such as oil, grease, or rust. Any contaminants on the surface of the aluminum can lead to porosity or other defects in the weld. Therefore, proper cleaning and preparation of the aluminum before welding is critical to achieving strong and durable welds.

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch