Aluminum Welding Wire

Wholesale Aluminum Welding Wire Manufacturers

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

-

View More

View More

SPECIAL AL ALLOY WELDING WIRE

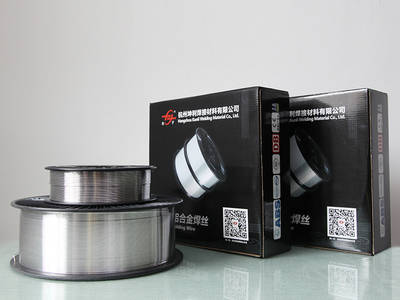

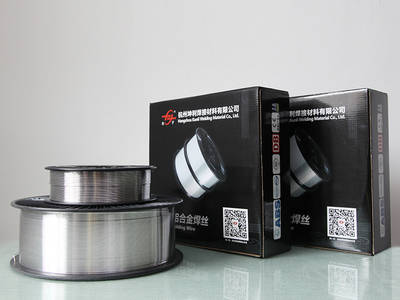

About Us

Coming From China, Marketing To The World.

Hangzhou Kunli welding materials Co., Ltd. is located in the industrial zone of Puyang Town, Xiaoshan District, Hangzhou, Zhejiang Province. It is a high-technology enterprise specializing in the research, development and manufacturing of high-performance China Aluminum Welding Wire manufacturers and wholesale Aluminum Welding Wire factory . The company has more than 20 years of aluminum alloy wire production experience, with international advanced Aluminum Welding Wire manufacturing equipment, complete testing equipment,stable production process and strict quality control system.

::: Last News :::

-

How does Aluminum Welding Wire avoid the impa...

May 09, 2024

In the aerospace field, for aluminum parts that have strict requirements for lightweight and high thermal conductivity, when using...

-

Gas-metal-arc welding (GMAW) is a common meth...

May 02, 2024

How to Weld Aluminum Welding WireAluminum Welding WireGas-metal-arc welding (GMAW) is a common method of welding aluminum alloys. ...

-

How to ensure high strength of the weld when ...

Apr 25, 2024

In the chemical industry, many equipment and pipelines need to handle corrosive media. When using Aluminum Welding Wire to weld al...

-

When using Aluminum Alloy Wire to weld alumin...

Apr 18, 2024

In the aerospace field, aluminum alloys are widely used in the manufacture of aircraft and spacecraft due to their light weight an...

Industry Information Extension

More Information About Aluminum Welding Wire

What is Aluminum Welding Wire

Aluminum welding wire is a type of filler metal that is used in the process of aluminum welding. It is made from aluminum alloy and is used to join two pieces of aluminum together. The wire is fed through a welding gun and is melted by the heat of the welding process, filling the gap between the two pieces of aluminum and bonding them together. Aluminum welding wire is typically available in a variety of alloys and diameters to suit different welding applications.

Advantages of Aluminum Welding Wire

1. There are several advantages of using aluminum welding wire for welding aluminum:

2. Lightweight: Aluminum is a lightweight metal, which makes it easy to handle and transport. This makes it an ideal choice for welding applications where weight is a concern.

3. High thermal conductivity: Aluminum has a high thermal conductivity, which allows for efficient heat transfer during the welding process. This helps to reduce the risk of warping or distortion of the metal.

4. Good corrosion resistance: Aluminum has good corrosion resistance, which makes it suitable for use in outdoor and marine applications.

5. High strength: When welded properly, aluminum can have a high strength-to-weight ratio, making it suitable for use in structures and other applications where strength is important.

6. Low cost: Aluminum is a relatively low-cost metal, which makes it an economical choice for many welding applications.

7. Easy to clean: Aluminum is easy to clean and maintain, which makes it suitable for use in food processing, pharmaceutical and other clean room applications.

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch